EN 10216-1压力用无缝钢管.交货技术条件:具有规定室温性能的非合金钢管

- 分类:国外产品技术与服务

- 作者:www.negerekli.com中燃管道

- 来源:英国ladbrokes官方网站

- 发布时间:2024-09-28

- 访问量:757

【概要描述】本欧洲标准规定了由非合金优质钢制成的具有指定室温性能的圆形横截面无缝管TR1和TR2的两种质量的交货技术条件。

EN 10216-1压力用无缝钢管.交货技术条件:具有规定室温性能的非合金钢管

【概要描述】本欧洲标准规定了由非合金优质钢制成的具有指定室温性能的圆形横截面无缝管TR1和TR2的两种质量的交货技术条件。

- 分类:国外产品技术与服务

- 作者:www.negerekli.com中燃管道

- 来源:英国ladbrokes官方网站

- 发布时间:2024-09-28

- 访问量:757

EN 10216-1 Seamless steel tubes for pressure purposes - Technical delivery conditions - Part 1: Non-alloy steel tubes with specified room temperature properties.

EN 10216-1压力用无缝钢管——交货技术条件——第1部分:具有规定室温性能的非合金钢管。

1.Scope范围

This European Standard specifies the technical delivery conditions for two qualities TR1 and TR2 of seamless tubes of circular cross section with specified room temperature properties made of non-alloy quality steel.

本欧洲标准规定了由非合金优质钢制成的具有指定室温性能的圆形横截面无缝管TR1和TR2的两种质量的交货技术条件。

NOTE:Once this standard is published in the Official Journal of the European Union (OJEU) under Directive 97/23/EC, presumption of conformity to the Essential Safety Requirements (ESR) of Directive 97/23/EC is limited to technical data of materials in this standard and does not presume adequacy of the material to a specific item of equipment. Consequently, the assessment of the technical data stated in this material standard against the design requirements of this specific item of equipment to verify that the ESRs of the Pressure Equipment Directive are satisfied,needs to be done by the designer or manufacturer of the pressure equipment, taking also into account the subsequent manufacturing processes which may affect properties of the base materials.

注:一旦本标准根据指令97/23/EC在欧盟官方公报(OJEU)上发布,对符合指令97/23/EC基本安全要求(ESR)的推定仅限于本标准中材料的技术数据,并不推定材料对特定设备项目的充分性。因此,压力设备的设计者或制造商需要根据该特定设备的设计要求对本材料标准中规定的技术数据进行评估,以验证是否满足《压力设备指令》的ESR,同时考虑到可能影响基材性能的后续制造工艺。

2. Normative references规范性引用文件

The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies. For undated references,the latest edition of the referenced document (including any amendments) applies.

以下文件全部或部分在本文件中被规范引用,对其应用不可或缺。凡是注日期的引用文件,仅引用的版本适用。对于未注明日期的引用文件,应采用引用文件的最新版本(包括任何修订)。

EN 10020, Definition and classification of grades of steel EN 10020,钢等级的定义和分类

EN 10021, General technical delivery conditions for steel products EN 10021,钢制品的一般交货技术条件

EN 10027-1, Designation systems for steels Part 1: Steel names EN 10027-1,钢的命名体系——第1部分:钢名称

EN 10027-2, Designation systems for steels Part 2: Numerical system EN 10027-2,钢的命名体系——第2部分:数字体系

EN 10052, Vocabulary of heat treatment terms for ferrous products EN 10052,铁制品热处理术语词汇

EN 10168, Steel products Inspection documents List of information and description EN 10168,钢制品——检验文件——信息和说明清单

EN 10204, Metallic products Types of inspection documents EN 10204,金属产品——检验文件类型

EN 10220, Seamless and welded steel tubes Dimensions and masses per unit length EN 10220,无缝和焊接钢管——单位长度的尺寸和质量

CEN/TR 10261, Iron and steel European standards for the determination of chemical composition CEN/TR 10261,钢铁——欧洲化学成分测定标准

EN 10266, Steel tubes, fittings and structural hollow sections Symbols and definitions of terms for use in product standards EN 10266,钢管、配件和结构空心型材产品标准中使用的术语符号和定义

EN ISO 148-1, Metallic materials Charpy pendulum impact test Part 1: Test method (ISO 148-1) EN ISO 148-1,金属材料夏比摆锤冲击试验第1部分:试验方法

EN ISO 377, Steel and steel products Location and preparation of samples and test pieces for mechanical testing (ISO 377) EN ISO 377,钢和钢制品——机械试验用样品和试件的位置和制备(ISO 377)

EN ISO 2566-1, Steel Conversion of elongation values Part 1: Carbon and low alloy steels(ISO 2566-1) EN ISO 2566-1,钢——伸长率值的转换——第1部分:碳钢和低合金钢

EN ISO 6892-1, Metallic materials Tensile testing Part 1: Method of test at room temperature(ISO 6892-1) EN ISO 6892-1,金属材料拉伸试验第1部分:室温试验方法

EN ISO 10893-1, Non-destructive testing of steel tubes Part 1:Automated electromagnetic testing of seamless and welded (except submerged arc-welded) steel tubes for the verification of hydraulic leaktightness (ISO 10893-1)

EN ISO 10893-1,钢管的无损检测——第1部分:用于验证液压密封性的无缝和焊接(埋弧焊除外)钢管的自动电磁检测

EN ISO 10893-2, Non-destructive testing of steel tubes Part 2: Automated eddy current testing of seamless and welded (except submerged arc-welded) steel tubes for the detection of imperfections (ISO 10893-2)

EN ISO 10893-2,钢管无损检测——第2部分:无缝和焊接(埋弧焊除外)钢管缺陷检测的自动涡流检测

EN ISO 10893-3,Non-destructive testing of steel tubes Part 3: Automated full peripheral flux leakage testing of seamless and welded (except submerged arc-welded) ferromagnetic steel tubes for the detection of longitudinal and/or transverse imperfections (ISO 10893-3)

EN ISO 10893-3,钢管的无损检测——第3部分:用于检测纵向和/或横向缺陷的无缝和焊接(埋弧焊除外)铁磁钢管的自动全周漏磁检测

EN ISO 10893-10, Non-destructive testing of steel tubes Part 10: Automated full peripheral ultrasonic testing of seamless and welded (except submerged arc-welded) steel tubes for the detection of longitudinal and/or transverse imperfections (ISO 10893-10)

EN ISO 10893-10,钢管的无损检测——第10部分:无缝和焊接(埋弧焊除外)钢管的自动全周超声波检测,用于检测纵向和/或横向缺陷

EN ISO 14284,Steel and iron Sampling and preparation of samples for the determination of chemical composition (ISO 14284)

EN ISO 14284,钢铁化学成分测定用样品的取样和制备(ISO 14284)

ISO 11484, Steel products Employer's qualification system for nondestructive testing (NDT) personnel ISO 11484,钢制品雇主无损检测(NDT)人员资格体系

3.Terms and definitions术语和定义

For the purposes of this document, the terms and definitions given in EN 10020, EN 10021, EN 10052,EN 10266 and the following apply.

就本文件而言,EN 10020、EN 10021、EN 10052、EN 10266和以下标准中给出的术语和定义适用。

3.1

employer雇主

organization for which a person works on a regular basis 一个人定期为之工作的组织

Note 1 to entry: The employer may be either the tube manufacturer or a third party organization providing non-destructive testing (NDT) services.

注1:雇主可以是管材制造商,也可以是提供无损检测(NDT)服务的第三方组织。

4.Symbols符号

For the purpose of this Part of EN 10216, the symbols given in EN 10266 apply.

就EN 10216的本部分而言,EN 10266中给出的符号适用。

5.Classification and designation分类和名称

Classification 分类

According to the classification system in EN 10020, the steels are classified as non-alloy quality steels.

根据EN 10020中的分类系统,这些钢被归类为非合金质量钢。

Designation任命

For the tubes covered by this Part of EN 10216 the steel designation consists of:

对于EN 10216本部分涵盖的管子,钢名称包括:

the number of this Part of EN 10216;

EN 10216本部分的编号;

plus either:加上:

the steel name in accordance with EN 10027-1;

符合EN 10027-1的钢材名称;

or:或者:

the steel number allocated in accordance with EN 10027-2.

根据EN 10027-2分配的钢号。

The steel name is designated by:

钢材名称由以下人员指定:

the capital letter P for pressure purposes;

大写字母P表示压力;

the indication of the specified minimum yield strength for thickness ≤ 16 mm, expressed in MPa(see Table 5 and Table 6);

厚度≤16mm的规定最小屈服强度的指示,单位为MPa(见表5和表6);

plus either:加上:

the alphanumeric TR1 for qualities without specified aluminium content, impact properties and specific inspection and testing requirements (see 9.1);

字母数字TR1表示没有指定铝含量、冲击性能和特定检验和测试要求的质量(见9.1);

or:或者:

the alphanumeric TR2 for qualities with specified aluminium content, impact properties and specific inspection and testing requirements.

字母数字TR2表示具有指定铝含量、冲击性能和特定检验和测试要求的质量。

6.Information to be supplied by the purchaser买方提供的信息

Mandatory information强制性信息

The following information shall be supplied by the purchaser at the time of enquiry and order:

买方应在询价和订购时提供以下信息:

the quantity (mass or total length or number);

数量(质量或总长度或数量);

the term “tube”;

术语“管”;

the dimensions (outside diameter D and wall thickness T) (see Table 7);

尺寸(外径D和壁厚T)(见表7);

the designation of the steel grade in accordance with this Part of EN 10216 (see 5.2).

根据EN 10216的本部分指定钢级(见5.2)。

Options选项

A number of options are specified in this Part of EN 10216 and these are listed below. In the event that the purchaser does not indicate a wish to implement any of these options at the time of enquiry and order, the tubes shall be supplied in accordance with the basic specification (see 6.1).

EN 10216的本部分规定了许多选项,如下所示。如果买方在询价和订购时没有表示希望实施这些选项中的任何一个,则应按照基本规范(见6.1)供应管材。

1) Delivery condition normalized or normalizing-formed for TR1 (see 7.2.2);

- TR1交付条件规范化或形成规范化(见7.2.2);

2) restriction on copper and tin contents (see Table 2 and Table 3); - 铜和锡含量限制(见表2和表3);

3) product analysis (see 8.2.2); - 产品分析(见8.2.2);

4) verification of longitudinal impact testing at −10 °C for quality TR2 (see Table 5 and Table 6); - 在-10°C下验证TR2质量的纵向冲击试验(见表5和表6);

5) selection of method for verification of leak-tightness (see 8.4.2.1); - 密封性验证方法的选择(见8.4.2.1);

6) Non-Destructive Testing for quality TR2 (see 8.4.2.2); the test method shall be specified by the purchaser; - TR2质量无损检测(见8.4.2.2);试验方法应由买方指定;

7) special end preparation (see 8.6); - 特殊端部准备(见8.6);

8) exact lengths (see 8.7.3); - 精确长度(见8.7.3);

9) inspection document 3.2 other than the standard document (see 9.2.1); - 标准文件以外的检验文件3.2(见9.2.1);

10) test unit restriction for tubes with D ≤ 76,1 mm of quality TR2 (see 10.1.1); - D≤76,1 mm质量TR2的管子的测试单位限制(见10.1.1);

11) wall thickness measurement away from the ends (see 11.5); - 远离端部的壁厚测量(见11.5);

12) additional marking (see 12.2); - 附加标记(见12.2);

13) protection (see 13).

13) 保护(见13)。

Example of an order订单示例

100 t of seamless tube with an outside diameter of 168.3 mm, a wall thickness of 4,5 mm, in accordance with EN 10216-1, made of steel grade P235TR2 with a 3.2 inspection certificate in accordance with EN 10204.

100吨外径为168.3毫米、壁厚为4.5毫米的无缝管,符合EN 10216-1标准,由P235TR2级钢制成,并具有符合EN 10204标准的3.2检验证书。

EXAMPLE 100 t - Tube – 168,3 × 4,5 - EN 10216-1 - P235TR2 - 3.2. 示例100吨-管材-168.3×4.5-EN 10216-1-P235TR2-3.2。

7.Manufacturing process制造工艺

Steelmaking process炼钢工艺

The steelmaking process is at the discretion of the manufacturer with the exception that the open hearth (Siemens-Martin) process shall not be employed unless in combination with a secondary steelmaking or ladle refining process.

炼钢工艺由制造商决定,除非与二次炼钢或钢包精炼工艺结合使用,否则不得采用平炉(西门子马丁)工艺。

Steels shall be fully killed.钢材应完全杀死。

NOTE This excludes the use of rimming, balanced or semi-killed steel.

注:这不包括使用沸腾钢、平衡钢或半镇静钢。

Tube manufacture and delivery conditions管材制造和交付条件

All NDT activities shall be carried out by qualified and competent level 1,2 and/or 3 personnel authorized to operate by the employer.

所有无损检测活动应由业主授权的合格、称职的1、2和/或3级人员进行。

The qualification shall be in accordance with ISO 11484 or, at least, an equivalent to it.资格认证应符合ISO 11484或至少与之相当的标准。

It is recommended that the level 3 personnel be certified in accordance with EN ISO 9712 or, at least, an equivalent to it.

建议3级人员按照EN ISO 9712或至少同等标准进行认证。

The operating authorization issued by the employer shall be in accordance with a written procedure.

雇主签发的操作授权应符合书面程序。

NDT operations shall be authorized by level 3 NDT individual approved by the employer.

无损检测操作应由雇主批准的3级无损检测人员授权。

NOTE The definition of level 1, 2 and 3 can be found in appropriate standards, e.g. EN ISO 9712 and ISO 11484.

注:1、2和3级的定义可以在适当的标准中找到,例如EN ISO 9712和ISO 11484。

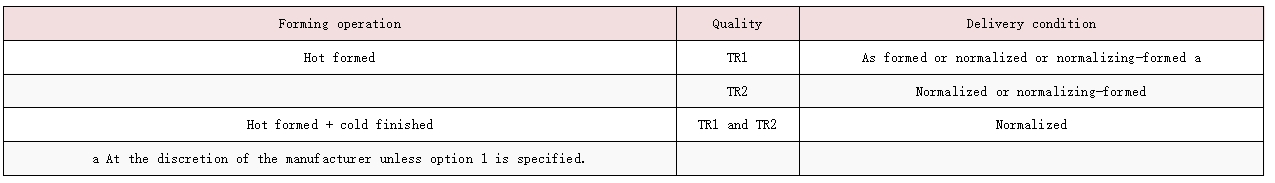

The tubes shall be manufactured by a seamless process. The forming operations and delivery conditions are shown in Table 1.

管子应采用无缝工艺制造。成型操作和交付条件如表1所示。

Table 1 — Forming operations and delivery conditions表1-成型操作和交付条件

Option 1 : The tube shall be supplied in normalized or normalizing-formed delivery condition.选项1:管子应在正火或正火成型交付条件下供应。

8. Requirements要求

8.1 General概述

When supplied in a delivery condition indicated in 7.2 and inspected in accordance with Clauses 9, 10 and 11,the tubes shall conform to the requirements of this Part of EN 10216.

当以7.2中所示的交付条件供应并按照第9、10和11条进行检查时,管子应符合EN 10216本部分的要求。

In addition, the general technical delivery requirements specified in EN 10021 shall apply.

此外,EN 10021中规定的一般技术交付要求应适用。

8.2 Chemical composition化学成分

8.2.1 Cast analysis铸件分析

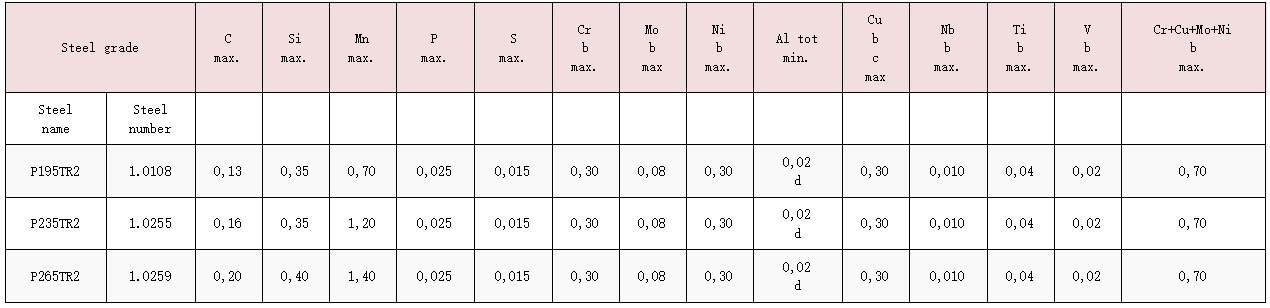

The cast analysis reported by the steel producer shall apply and conform to the requirements of Table 2 for quality TR2 and in Table 3 for quality TR1.

钢铁生产商报告的铸件分析应适用并符合表2中质量TR2和表3中质量TR1的要求。

When welding tubes are produced in accordance with this Part of EN 10216, account should be taken of the fact that the behaviour of the steel during and after welding is dependent not only on the steel, but also on the applied heat treatment and the conditions of preparing for and carrying out the welding.

当根据EN 10216的本部分生产焊接管时,应考虑到焊接期间和之后钢的行为不仅取决于钢,还取决于所应用的热处理以及焊接准备和实施的条件。

Table 2 — Chemical composition (cast analysis) a in % by mass for quality TR2表2--质量TR2的化学成分(铸件分析)a质量百分比

a Elements not included in this Table shall not be intentionally added to the steel without the agreement of the purchaser, except for elements which may be added for finishing the cast. All appropriate measures shall be taken to prevent the addition of undesirable elements from scrap or other materials used in the steelmaking process.

a未经买方同意,不得有意将本表中未包含的元素添加到钢中,但为完成铸件而添加的元素除外。应采取一切适当措施,防止在炼钢过程中使用的废料或其他材料中添加不需要的元素。

b The content of these elements need not be reported unless intentionally added to the cast.

b除非有意添加到铸件中,否则不需要报告这些元素的含量。

c Option 2: In order to facilitate subsequent forming operation, an agreed maximum copper content lower than indicated and an agreed specified maximum tin content shall apply.

c选项2:为了便于后续成型操作,应采用低于指示的商定最大铜含量和商定的规定最大锡含量。

d This requirement is not applicable provided the steel contains a sufficient amount of other nitrogen binding elements which shall be reported.

d如果钢中含有足够量的其他氮结合元素,则此要求不适用,应予以报告。

Table 3 —Chemical composition (cast analysis) a in % by mass for quality TR1表3--质量TR1的化学成分(铸件分析)a质量百分比

a Elements not included in this table shall not be intentionally added to the steel without the agreement of the purchaser, except for elements which may be added for finishing the cast. All appropriate measures shall be taken to prevent the addition of undesirable elements from scrap or other materials used in the steelmaking process.

a未经买方同意,不得有意将本表中未包含的元素添加到钢中,但为完成铸件而添加的元素除外。应采取一切适当措施,防止在炼钢过程中使用的废料或其他材料中添加不需要的元素。

b The content of these elements need not be reported unless intentionally added to the cast.

b除非有意添加到铸件中,否则不需要报告这些元素的含量。

c Option 2:In order to facilitate subsequent forming operation, an agreed maximum copper content lower than indicated and an agreed specified maximum tin content shall apply.

c选项2:为了便于后续成型操作,应采用低于指示的商定最大铜含量和商定的规定最大锡含量。

d These grades do not support the Essential Requirements of the New Approach Directive 97/23/EC.

d这些等级不符合新方法指令97/23/EC的基本要求。

8.2.2 Product analysis产品分析

Option 3: A product analysis for tubes of quality TR2 shall be supplied. For tubes with outside diameter less than or equal to 76, 1 mm this option applies only in combination with Option 11.

选项3:应提供TR2质量管的产品分析。对于外径小于或等于76、1 mm的管子,此选项仅与选项11结合使用。

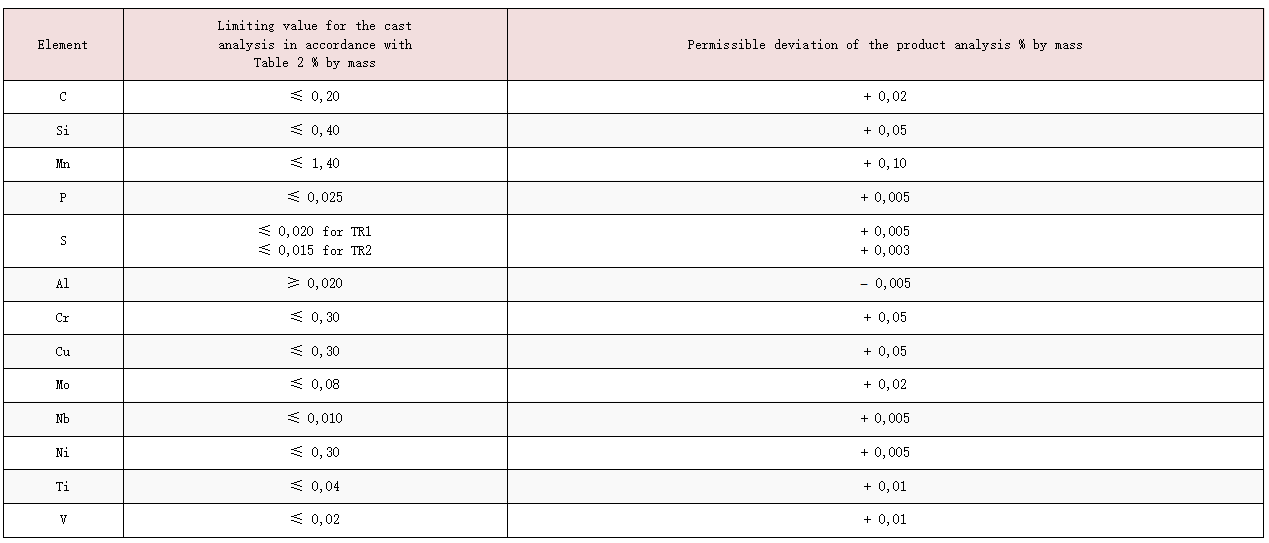

Table 4 specifies the permissible deviations of the product analysis from the specified limits on cast analysis given in Table 2 and Table 3.

表4规定了产品分析与表2和表3中给出的铸件分析规定限值的允许偏差。

Table 4 —Permissible deviations of the product analysis from specified limits on cast analysis given in Tables 2 and 3

表4——产品分析与表2和表3中给出的铸件分析规定限值的允许偏差

8.3 Mechanical properties机械性能

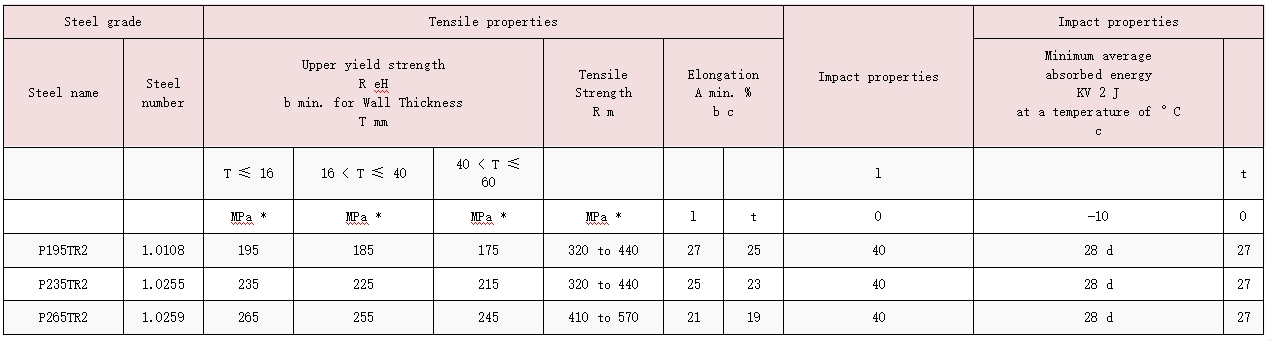

8.3.1 Mechanical properties for quality TR2质量TR2的机械性能

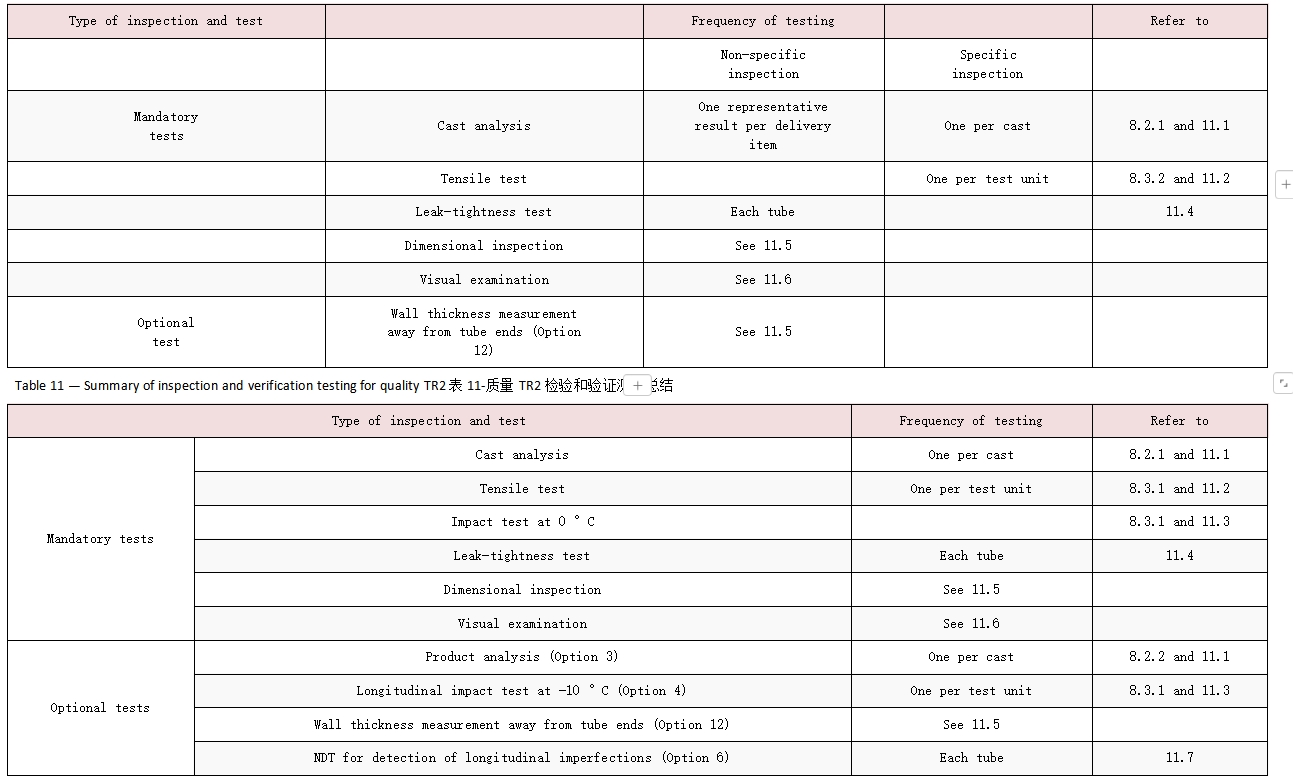

The mechanical properties of the tubes shall conform to the requirements of Table 5 for grade TR2 irrespective of whether they are verified or not (see Table 11).

管子的机械性能应符合表5中TR2级的要求,无论是否经过验证(见表11)。

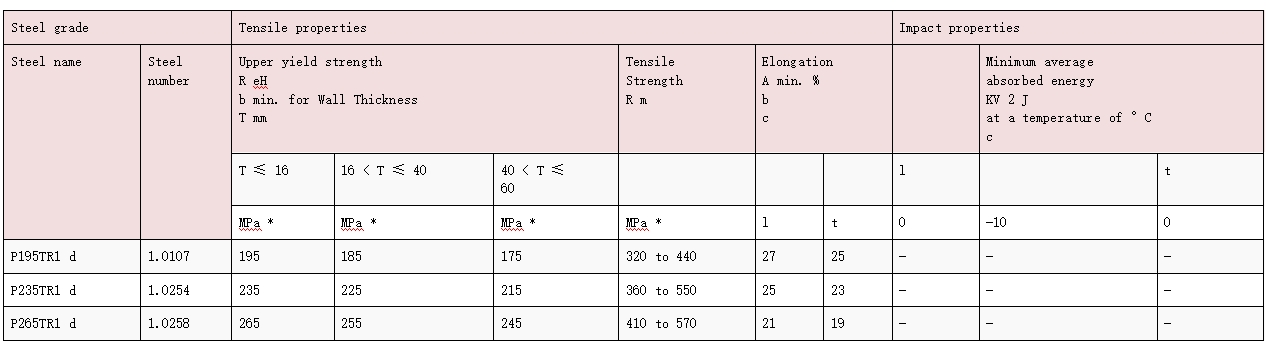

Table 5 — Mechanical properties for quality TR2 a表5--质量TR2 a的机械性能

a For wall thickness greater than 60 mm the mechanical properties are subject to agreement.a对于大于60mm的壁厚,机械性能须经双方同意。

b See 11.2.

c l = longitudinal t = transverse

d Option 4: In addition to the test in Table 11, longitudinal impact strength shall be verified at - 10 °C.

*1 MPa = 1 N/mm 2

8.3.2 Mechanical properties for quality TR1

8.3.2质量TR1的机械性能

The mechanical properties of the tubes shall conform to the requirements of Table 6 for grade TR1 irrespective of whether they are verified or not (see Table 10).

管子的机械性能应符合表6中TR1级的要求,无论是否经过验证(见表10)。

Table 6 — Mechanical properties for quality TR1 a

表6-TR1 a质量的机械性能

a For wall thickness greater than 60 mm the mechanical properties are subject to agreement.

a对于大于60mm的壁厚,机械性能须经双方同意。

b See 11.2.

c l = longitudinal t = transverse

d These grades do not support the Essential Requirements of the New Approach Directive 97/23/EC.

* 1 MPa = 1 N/mm

8.4 Appearance and internal soundness

8.4外观和内部坚固性

8.4.1 Appearance外观

8.4.1.1 The tubes shall be free from external and internal surface defects that can be detected by visual examination.

8.4.1.1管子应无肉眼可见的内外表面缺陷。

8.4.1.2 The internal and external surface finish of the tubes shall be typical of the manufacturing process and,where applicable, the heat treatment employed. Normally the finish and surface condition shall be such that any surface imperfections requiring dressing can be identified.

8.4.1.2管子的内外表面光洁度应符合制造工艺的典型要求,并在适用的情况下采用热处理。通常,表面光洁度和表面状况应能识别出任何需要修整的表面缺陷。

8.4.1.3 It shall be permissible to dress, only by grinding or machining, surface imperfections provided that,after doing so, the wall thickness in the dressed area is not less than the specified minimum wall thickness. All dressed areas shall blend smoothly into the contour of the tube.

8.4.1.3只允许通过研磨或机加工来修整表面缺陷,前提是修整后,修整区域的壁厚不小于规定的最小壁厚。所有修整区域应平滑地融入管道轮廓。

8.4.1.4 Surface imperfections which encroach on the specified minimum wall thickness shall be considered defects and tubes containing these shall be deemed not to conform to this Part of this EN 10216.

8.4.1.4侵犯规定最小壁厚的表面缺陷应被视为缺陷,含有这些缺陷的管子应被视不符合本EN 10216的本部分。

8.4.2 Internal soundness内部稳健性

8.4.2.1 Leak-tightness密封性

The tubes shall pass a hydrostatic test (see 11.4.1) or electromagnetic test (see 11.4.2) for leak-tightness.Unless the Option 5 is specified the choice of the test method is at the discretion of the manufacturer.

管子应通过水压试验(见11.4.1)或电磁试验(见114.2)进行密封性测试。除非指定了选项5,否则测试方法的选择由制造商自行决定。

Option 5: The test method for verification of leak-tightness in accordance with 11.4.1 or 11.4.2 is specified by the purchaser.

选项5:买方规定了根据11.4.1或11.4.2验证密封性的试验方法。

8.4.2.2 Non-Destructive Testing无损检测

Option 6: The tubes of quality TR2 shall pass a non-destructive test for the detection of longitudinal imperfections in accordance with 11.7. The test method shall be specified by the purchaser

选项6:根据11.7,质量为TR2的管子应通过无损检测,以检测纵向缺陷。试验方法应由买方指定

8.5 Straightness直线度

The deviation from straightness, of any tube length L shall not exceed 0,001 5 L. Deviations from straightness over any one metre length shall not exceed 3 mm.

任何管长L的直线度偏差不得超过0001 5 L。任何一米长度的直线度误差不得超过3 mm。

8.6 Preparation of ends端部准备

Tubes with wall thickness ≥ 3,2 mm shall be delivered with square cut ends. The ends shall be free from excessive burrs.

壁厚≥3.2mm的管子应交付方形切割端。端部应无过多毛刺。

Option 7: The tubes with wall thickness ≥ 3.2 mm shall be delivered with bevelled ends (see Figure 1). The bevel shall have an angle α of 30°( +°5,-0°)with a root face C of 1,6 mm ± 0,8 mm, except that for wall thickness T greater than 20 mm, an agreed alternative bevel may be specified.

选项7:壁厚≥3.2mm的管子应交付斜切端(见图1)。斜面的角度α应为30°(+°5,-0°),根部面C为1.6 mm±0.8 mm,但壁厚T大于20 mm的情况除外,可以指定商定的替代斜面。

Key

D outside diameter D外径

α bevel angle α斜角

C root face of bevelled end C斜切端的根面

8.7 Dimensions, masses and tolerances尺寸、质量和公差

8.7.1 Diameter and wall thickness直径和壁厚

Tubes shall be delivered by outside diameter D and wall thickness T.

管子应按外径D和壁厚T交付。

Preferred outside diameters D and wall thicknesses T have been selected from EN 10220 and are given in Table 7.

优选的外径D和壁厚T已从EN 10220中选择,并在表7中给出。

Dimensions which are different from those in Table 7 may be agreed.

与表7中不同的尺寸可以达成一致。

8.7.2 Mass质量

For the mass per unit length the provisions of EN 10220 apply.

对于单位长度的质量,EN 10220的规定适用。

8.7.3 Lengths长度

Unless Option 8 is specified the tubes are delivered in random lengths. The delivery range shall be agreed at the time of enquiry and order.

除非指定了选项8,否则管道的交付长度是随机的。交货范围应在询价和订购时商定。

Option 8: The tubes shall be delivered in exact lengths and the length shall be specified at the time of enquiry and order. For the tolerances, see 8.7.4.2.l

选项8:管子应按精确长度交付,长度应在询价和订购时指定。公差见8.7.4.2.l

8.7.4 Tolerances公差

8.7.4.1 Tolerances on diameter and thickness直径和厚度公差

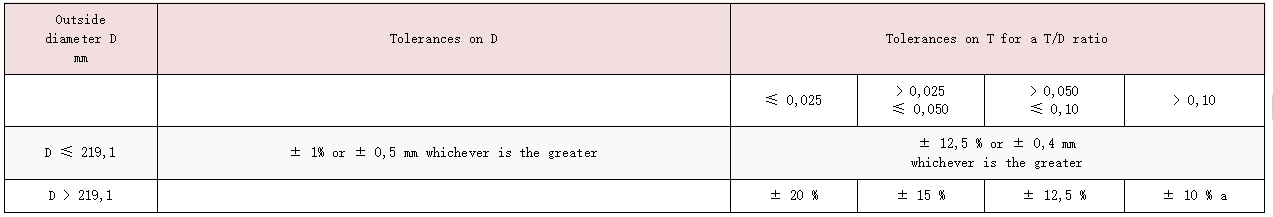

The diameter and the wall thickness of the tubes shall be within the tolerance limits given in Table 8.

管子的直径和壁厚应在表8给出的公差范围内。

Out-of-roundness is included in the tolerances on outside diameter and eccentricity is included in the tolerances on wall thickness.

不圆度包含在外径公差中,偏心度包含在壁厚公差中。

Table 8 — Tolerances on outside diameter and on wall thickness表8——外径和壁厚公差

a For outside diameters D ≥ 355,6 mm it is permitted to exceed the upper wall thickness locally by a further 5 % of the wall thickness T

a对于外径D≥355,6 mm,允许局部超过上壁厚5%的壁厚T

8.7.4.2 Tolerances on exact lengths精确长度公差

The tolerances for exact lengths shall be as given in Table 9.精确长度的公差应如表9所示。

Table 9 — Tolerances on exact lengths表9——精确长度公差

Dimensions in millimetres尺寸单位为毫米

|

Length L |

Tolerance on exact length |

|

L ≤ 6 000 |

+ 10 |

|

6 000 < L ≤ 12 000 |

+15 |

|

L > 12 000 |

+by agreement |

9 Inspection检查

9.1 Types of inspection检查类型

Conformity to the requirements of the order, for tubes in accordance with this Part of EN 10216, shall be verified by:

对于符合EN 10216本部分的管子,应通过以下方式验证其是否符合订单要求:

non-specific or specific inspection for quality TR1; TR1的非特定或特定质量检查;

specific inspection for quality TR2. TR2质量专项检查。

When an inspection certificate 3.1 is specified, the material manufacturer shall state in the confirmation of the order whether he is operating according to a “quality-assurance system”, certified by a competent Body established within the Community, and having undergone a specific assessment for materials.

当指定了检验证书3.1时,材料制造商应在订单确认书中说明其是否按照“质量保证体系”运行,该体系由共同体内设立的主管机构认证,并已对材料进行了具体评估。

NOTE See the EU Directive 97/23/EC, Annex I, section 4.3 third paragraph and for further information the Guidelines of the EU Commission and the Member States for its interpretation (see e.g. Guidelines 7/2 and 7/16).

注:见欧盟指令97/23/EC,附件一,第4.3节第三段,更多信息见欧盟委员会和成员国的指南(例如,见指南7/2和7/16)。

9.2 Inspection documents检验文件

9.2.1 Types of inspection documents检验文件类型

The following inspection documents, in accordance with EN 10204, shall be issued;应根据EN 10204发布以下检验文件;

- test report 2.2 for quality TR1; -TR1质量测试报告2.2;

- inspection certificate 3.1 for quality TR2. -质量检验证书3.1 TR2。

Option 9: One of the following inspection documents, specified by the purchaser, shall be issued:

选项9:应出具买方指定的以下检验文件之一:

- for quality TR1 specific inspection with inspection certificate 3.2;

-用于质量TR1特定检查,并附有检验证书3.2;

- for quality TR2, an inspection certificate 3.2.

-对于质量TR2,检验证书为3.2。

If an inspection certificate 3.2 is specified, the purchaser shall notify the manufacturer of the name and address of the organization or person who is to carry out the inspection and produce the inspection document, and it shall be agreed which party shall issue the certificate.

如果规定了检验证书3.2,买方应通知制造商进行检验并出示检验文件的组织或人员的名称和地址,并应商定由哪一方颁发证书。

Document 3.1 and 3.2 are to be validated by the manufacturer’s authorized representative.

文件3.1和3.2应由制造商授权代表验证。

9.2.2 Content of inspection documents检验文件内容

9.2.2.1 The content of the inspection document shall be in accordance with EN 10168 as shown in 9.2.2.2 and9.2.2.3.

9.2.2.1 检验文件的内容应符合EN 10168,如9.2.2.2和9.2.2.3所示。

In all types of inspection documents, a statement on the conformity of the products delivered with the requirements of this specification and the order shall be included.

在所有类型的检验文件中,应包括一份关于交付产品符合本规范和订单要求的声明。

9.2.2.2 For tubes supplied with non-specific inspection, the test report shall contain the following codes and information:

9.2.2.2对于提供非特定检验的管子,试验报告应包含以下代码和信息:

A commercial transactions and parties involved;商业交易和相关方;

B description of products to which the inspection document applies;检验文件适用的产品说明;

C02 direction of test pieces; C02试样方向;

C10–C13 tensile test; C10-C13拉伸试验;

C71–C92 chemical composition;C71-C92化学成分;

D01 marking and identification, surface appearance, shape and dimensional properties; D01标记和标识、表面外观、形状和尺寸特性;

D02–D99 leak-tightness test; D02-D99密封性试验;

Z validation. Z验证。

9.2.2.3 For tubes supplied with specific inspection the inspection certificate shall contain the following codes and information:

9.2.2.3对于经过特定检验的管子,检验证书应包含以下代码和信息:

A commercial transactions and parties involved;

A 商业交易及其涉及的各方;

B description of products to which the inspection document applies

B检验文件适用的产品说明

C02–C03 direction of test pieces and testing temperature; C02-C03试样方向和试验温度;

C10–C13 tensile test; C10-C13拉伸试验;

C40–C43 impact test, if applicable; C40-C43冲击试验(如适用);

C71–C92 chemical composition on cast analysis (product analysis if applicable); C71-C92铸件化学成分分析(如适用,进行产品分析);

D01 marking and identification, surface appearance, shape and dimensional properties; D01标记和标识、表面外观、形状和尺寸特性;

D02–D99 leak-tightness test; NDT if applicable; D02-D99密封性试验;无损检测(如适用);

Z validation. Z验证。

In addition, for inspection document 3.1 the manufacturer shall state the references to the certificate (see 9.1) of the appropriate “quality-assurance system“, if applicable

此外,对于检验文件3.1,制造商应说明适当的“质量保证体系”证书(见9.1)的参考(如适用)

9.3 Summary of inspection and verification testing检验和验证测试总结

Table 10 — Summary of inspection and verification testing for quality TR1表10——TR1质量检验和验证测试总结

10 Sampling取样

10.1 Frequency of tests测试频率

10.1.1 Test unit测试单元

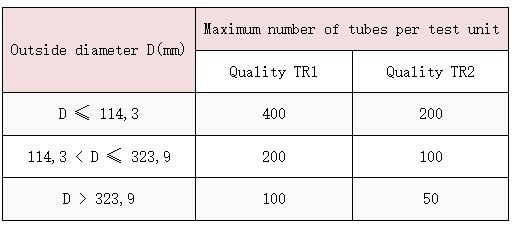

In case of specific inspection, a test unit shall comprise:

在特定检查的情况下,测试单元应包括:

Quality TR1: Tubes of the same specified outside diameter and wall thickness, the same steel grade, the same manufacturing process and, if applicable, the same normalising treatment in a continuous furnace or heat-treated in the same furnace charge in a batch-type furnace.

质量TR1:具有相同规定外径和壁厚、相同钢种、相同制造工艺的管子,如果适用,在连续炉中进行相同的正火处理,或在间歇式炉中在相同炉料中进行热处理。

Quality TR2: Tubes of the same specified outside diameter and wall thickness, the same steel grade, the same cast, the same manufacturing process and, if applicable, the same normalising treatment in a continuous furnace or heat-treated in the same furnace charge in a batch-type furnace. Tubes with specified outside diameter less than or equal to 76.1 mm need not be separated by cast unless Option 10 is specified.

质量TR2:具有相同规定外径和壁厚、相同钢号、相同铸件、相同制造工艺的管子,如果适用,在连续炉中进行相同的正火处理,或在间歇式炉中在相同炉料中进行热处理。除非指定了选项10,否则指定外径小于或等于76.1mm的管子不需要通过铸造分开。

The number of tubes, in manufacturing lengths, per test unit shall conform to Table 12.

每个试验单元的管子数量(以制造长度计)应符合表12。

The manufacturing length (e.g. the rolled length after the normalising forming process) may differ from the delivery length providing there is no additional HT after cutting the manufacturing lengths into individual lengths.

制造长度(例如正火成形工艺后的轧制长度)可能与交付长度不同,前提是在将制造长度切割成单个长度后没有额外的HT。

Option 10: Tubes with specified outside diameter less than or equal to 76,1 mm shall be separated by cast for quality TR2 .

选项10:规定外径小于或等于76,1 mm的管子应通过铸件隔开,以获得TR2质量。

Table 12 — Number of tubes per test unit表12——每个测试单元的试管数量

10.1.2 Number of sample tubes per test unit每个测试单元的样品管数量

One sample tube shall be taken from each test unit.每个测试单元应取一个样品管。

10.2 Preparation of samples and test pieces样品和试件的制备

10.2.1 Selection and preparation of samples for product analysis Samples for product analysis shall be taken from the test pieces or samples for mechanical testing or from the whole thickness of the tube at the same location as the mechanical test samples, in accordance with EN ISO 14284.

10.2.1产品分析样品的选择和制备根据EN ISO 14284,产品分析样品应从机械测试的试样或样品中取出,或从与机械测试样品相同位置的整个管子厚度中取出。

10.2.2 Location, orientation and preparation of samples and test pieces for mechanical tests 机械试验样品和试件的位置、方向和制备

10.2.2.1 General概述

Samples and test pieces shall be taken at the tube ends and in accordance with the requirements of EN ISO 377.应按照EN ISO 377的要求在管端取样和试件。

10.2.2.2 Test pieces for tensile test拉伸试验用试样

The test pieces for tensile test shall be prepared in accordance with EN ISO 6892-1.拉伸试验的试样应按照EN ISO 6892-1制备。

At the manufacturer's discretion:制造商可自行决定:

for tubes with an outside diameter D ≤ 219,1 mm the test piece shall be either a full tube section or a strip section and shall be taken in a direction longitudinal to the axis of the tube;

对于外径D≤219.1 mm的管子,试样应为全管段或条形段,并应沿管子轴线的纵向截取;

for tubes with an outside diameter D > 219,1 mm the test piece shall either a machined test piece with circular cross section from an unflattened sample or a strip section and be taken in a direction either longitudinal or transverse to the axis of the tube. 对于外径D>219.1 mm的管子,试件应为未抛光样品或条形截面的圆形横截面机加工试件,并沿管子轴线的纵向或横向取样。

10.2.2.3 Test pieces for impact test冲击试验试样

Three standard Charpy V-notch test pieces shall be prepared in accordance with EN ISO 148-1. If the wall thickness is such that standard test pieces cannot be produced without flattening of the section, then test pieces of width less than 10 mm, but not less than 5 mm shall be prepared; the largest obtainable width shall be used.

应按照EN ISO 148-1制备三个标准夏比V型缺口试样。如果壁厚使得在不压平截面的情况下无法生产标准试件,则应准备宽度小于10mm但不小于5mm的试件;应使用可获得的最大宽度。

Where test pieces at least 5 mm width cannot be obtained, the tubes shall not be subjected to impact testing.

如果无法获得至少5mm宽的试样,则不得对管子进行冲击试验。

Unless otherwise specified (see Option 4), the test pieces shall be taken transverse to the tube axis unless D min , as calculated by the following equation, is greater than the specified outside diameter, in which case longitudinal test pieces shall be used:

除非另有规定(见选项4),否则应横向于管轴取试样,除非由以下方程式计算的D min大于规定的外径,在这种情况下,应使用纵向试样:

D min = (T-5) + [ 756,25 / (T-5) ] (1)

The test pieces shall be prepared such that the axis of the notch is perpendicular to the surface of the tube,see Figure 2.

试样的制备应使缺口轴线垂直于管表面

1 longitudinal test piece 1个纵向试件

2 transverse test piece 2个横向试件

w specimen width w试样宽度

11 Verification test methods验证试验方法

11.1 Chemical analysis化学分析

The elements to be determined and reported shall be those specified in Table 2. The choice of a suitable physical or chemical analytical method for the analysis shall be at the discretion of the manufacturer. In cases of dispute, the method used shall be agreed between manufacturer and purchaser taking into account CEN/TR 10261.

待确定和报告的元素应为表2中规定的元素。制造商应自行决定选择合适的物理或化学分析方法进行分析。如有争议,制造商和买方应考虑CEN/TR 10261,就使用的方法达成一致。

11.2 Tensile test拉伸试验

The test shall be carried out at room temperature in accordance with EN ISO 6892-1, and the following shall be determined:

应按照EN ISO 6892-1在室温下进行试验,并应确定以下内容:

the tensile strength (R m );抗拉强度(Rm);

the upper yield strength (R eH ) or if a yield phenomenon is not present the 0,2 % proof strength (R p0,2 );屈服强度上限(R eH),或者如果不存在屈服现象,则为0.2%的屈服强度(R p0,2);

the percentage elongation after fracture with a reference to a gauge length ( L 0 ) of So ⋅ 65 , 5 ; if a nonproportional test piece is used, the percentage elongation value shall be converted to the value for a gauge length So Lo ⋅ = 65 , 5 using the conversion tables in EN ISO 2566-1.断裂后相对于标距长度(L 0)的伸长率为So⋅65,5;如果使用非比例试样,则应使用EN ISO 2566-1中的转换表将伸长率值转换为标距长度So Lo⋅=65,5的值。

11.3 Impact test冲击试验

11.3.1 The test shall be carried out (but see 10.2.2.3) in accordance with EN ISO 148-1 at 0 °C and, if option 4 is specified, at -10 °C.

11.3.1 应按照EN ISO 148-1在0°C下进行测试(但见10.2.2.3),如果指定了选项4,则应在-10°C下。

11.3.2 The mean value of the three test pieces shall meet the requirements given in Table 5 and Table 6. One individual value may be below the specified value, provided that it is not less than 70 % of that value.

11.3.2 三个试样的平均值应符合表5和表6中给出的要求。一个单独的值可能低于指定值,前提是它不小于该值的70%。

11.3.3 If the width (W) of the test piece is less than 10 mm, the measured impact energy (KV p ) shall be converted to the calculated impact energy( KV c ) using the following equation:

11.3.3如果试件的宽度(W)小于10 mm,则应使用以下方程式将测量的冲击能量(KV p)转换为计算的碰撞能量(KV c):

where

KV c is the calculated impact energy, in joules; KV c是计算出的冲击能量,单位为焦耳;

KV p is the measured impact energy, in joules; KV p是测量的冲击能量,单位为焦耳;

W is the width of the test piece, in millimetres. W是试样的宽度,单位为毫米。

The calculated impact energy KV c shall conform to the requirements given in 11.3.2. 计算出的冲击能量KV c应符合11.3.2中给出的要求。

11.3.4 If the requirements of 11.3.2 are not met, then an additional set of three test pieces may be taken at the discretion of the manufacturer from the same sample and tested. To consider the test unit as conforming, after testing the second set, the following conditions shall be satisfied simultaneously:

11.3.4如果不符合11.3.2的要求,则制造商可自行决定从同一样品中额外取三个试样进行测试。为了认为测试单元合格,在测试第二组后,应同时满足以下条件:

the average value of the six tests shall be equal to or greater than the specified minimum value; 六次试验的平均值应等于或大于规定的最小值;

not more than two of the six individual values may be lower than the specified minimum value; 六个单独值中不超过两个可能低于指定的最小值;

not more than one of the six individual values may be lower than 70 % of the specified minimum average value. 六个单独值中不超过一个可以低于指定最小平均值的70%。

11.3.5 The dimensions in millimetres of the test pieces, the measured impact energy values and the resulting average value shall be reported.

11.3.5应报告试样的尺寸(单位:毫米)、测量的冲击能量值和由此产生的平均值。

11.4 Leak tightness test密封性试验

11.4.1 Hydrostatic test水压试验

The hydrostatic test shall be carried out at a test pressure of 70 bar 1) or at a test pressure P calculated using the following equation, whichever is lower:

静水压试验应在70 bar 1)的试验压力或使用以下方程式计算的试验压力P下进行,以较低者为准:

where

P is the test pressure, in bar;P是试验压力,单位为bar;

D is the specified outside diameter, in millimetres;D为规定外径,单位为毫米;

T is the specified wall thickness, in millimetres; T是规定的壁厚,单位为毫米;

S is the stress, in MPa, corresponding to 70 % of the specified minimum yield strength (see Table 5 and Table 6) for the steel grade concerned.

S是对应于相关钢种规定最小屈服强度(见表5和表6)70%的应力,单位为MPa。

The test pressure shall be held for not less than 5 s for tubes with an outside diameter D less than or equal to 457 mm and for not less than 10 s for tubes with an outside diameter D greater than 457 mm.

对于外径D小于或等于457 mm的管子,试验压力应保持不少于5 s,对于外径D大于457 mm的管,试验压力保持不少于10 s。

The tube shall withstand the test without showing leakage.管子应能承受试验,而不会出现泄漏。

NOTE This hydrostatic leak-tightness test is not a strength test.注:此静水压密封性试验不是强度试验。

11.4.2 Electromagnetic test电磁试验

The test shall be carried out in accordance with EN ISO 10893-1.试验应按照EN ISO 10893-1进行。

11.5 Dimensional inspection尺寸检查

Specified dimensions, including straightness, shall be verified.应验证规定的尺寸,包括直线度。

The outside diameter shall be measured at tube ends. For tubes with outside diameter D ≥ 406,4 mm, the diameter may be measured using a circumference tape.

外径应在管端测量。对于外径D≥406.4mm的管子,可以使用周长带测量直径。

Unless Option 11 is specified the wall thickness shall be measured at both tube ends.

除非指定了选项11,否则应在管两端测量壁厚。

Option 11: The wall thickness shall be measured away from the tube ends in accordance with an agreed procedure.

选项11:应按照商定的程序在远离管端的地方测量壁厚。

扫二维码用手机看

- 联系电话- 0317-6689999 6165555

- 业务邮箱- 9905791@qq.com

- 公司地址- 河北省沧州市盐山县千童大街沧州银行对面

- 联系电话- 0317-6689999 6165555

- 业务邮箱- 9905791@qq.com

- 公司地址- 河北省沧州市盐山县千童大街沧州银行对面

版权所有:英国ladbrokes官方网站 冀ICP备19004948号-6

热线:0317-6165555

热线:0317-6165555 9905791@qq.com

9905791@qq.com