EN 10216系列规定了各种尺寸的冷加工精密钢管的标准

- 分类:国外产品技术与服务

- 作者:www.negerekli.com中燃管道

- 来源:英国ladbrokes官方网站

- 发布时间:2024-09-28

- 访问量:421

【概要描述】EN 10216系列规定了各种尺寸的冷加工精密钢管的标准。由于其连续的尺寸和与热精加工管相比改进的公差和表面,精密钢管在机械工程中的应用越来越多。EN 10216系列无缝管主要用于压力目的,如桶或活塞

EN 10216系列规定了各种尺寸的冷加工精密钢管的标准

【概要描述】EN 10216系列规定了各种尺寸的冷加工精密钢管的标准。由于其连续的尺寸和与热精加工管相比改进的公差和表面,精密钢管在机械工程中的应用越来越多。EN 10216系列无缝管主要用于压力目的,如桶或活塞

- 分类:国外产品技术与服务

- 作者:www.negerekli.com中燃管道

- 来源:英国ladbrokes官方网站

- 发布时间:2024-09-28

- 访问量:421

EN 10216 series specified the standard of cold processed precision steel tubes in a wide range of sizes.

EN 10216系列规定了各种尺寸的冷加工精密钢管的标准。

The EN 10216 series specified the standard of cold processed precision steel tubes in a wide range of sizes. Thanks to their continuous sizes and improved tolerances and surfaces compared with hot finished tubes, precision steel tubes are finding increasing use as mechanical engineering. EN 10216 series seamless tubes are mainly used for for pressure purposes such as barrel or piston.

EN 10216系列规定了各种尺寸的冷加工精密钢管的标准。由于其连续的尺寸和与热精加工管相比改进的公差和表面,精密钢管在机械工程中的应用越来越多。EN 10216系列无缝管主要用于压力目的,如桶或活塞。

EN 10216 is a standard which covers steel grade P235TR2, which are well suited for pressure applications. Furthermore, European Standard EN 10216-1 specifies the technical delivery conditions for two qualities steels i.e. en 10216-1 p235tr1 and TR2.

EN 10216是一个标准,涵盖了P235TR2级钢,非常适合压力应用。此外,欧洲标准EN 10216-1规定了两种质量钢的技术交付条件,即EN 10216-1 p235tr1和TR2。

This part of EN1026 specifies the technical delivery conditions in two test categories for seamless tubes for circular cross section, with specified elevated temperature properties, made of non-alloy and alloy steel.

EN1026的这一部分规定了由非合金钢和合金钢制成的具有指定高温性能的圆形横截面无缝管的两个试验类别的技术交付条件。

Application应用

- For producing storage tanks of heat-resistant steels used in boiler-making, tool-making;·用于生产用于锅炉制造、工具制造的耐热钢储罐;

- For constructing pressure reservoirs and high pressure are simultaneously used to have summarized load and special conditions.·为了建设压力水库,同时使用高压来总结负荷和特殊条件。

EN 10216 Seamless steel tubes for pressure purposes EN 10216压力用无缝钢管

- EN 10216-1 Non-alloy steel tubes with specified room temperature properties·EN 10216-1具有规定室温性能的非合金钢管

- EN 10216-2 Non alloy and alloy steel tubes with specified elevated temperature properties·EN 10216-2具有规定高温性能的非合金和合金钢管

- EN 10216-3 Alloy fine grain steel tubes·EN 10216-3合金细晶粒钢管

- EN 10216-4 Non-alloy and alloy steel tubes with specified low temperature properties·EN 10216-4具有规定低温性能的非合金和合金钢管

- EN 10216-5 Stainless steel tubes·EN 10216-5不锈钢管

DIN EN 10216-1

Seamless steel tubes for pressure purposes - Technical delivery conditions -Part 1: Non-alloy steel tubes with specified room temperature properties

承压用无缝钢管交货技术条件第1部分:具有规定室温性能的非合金钢管

Specifies the technical delivery conditions for two qualities, T1 and T2, of seamless tubes of circular cross section, with specified room temperature properties, made of non-alloy quality steel.

规定了由非合金质量钢制成的具有指定室温性能的圆形横截面无缝管的两种质量T1和T2的技术交付条件。

DIN EN 10216-2

Seamless steel tubes for pressure purposes - Technical delivery conditions - Part 2: Non alloy and alloy steel tubes with specified elevated temperature properties; German version EN 10216-2:2002+A2:2007

压力用无缝钢管.交货技术条件.第2部分:具有规定高温性能的非合金和合金钢管;德文版EN 10216-2:2002+A2:2007

The document specifies the technical delivery conditions in two test categories for seamless tubes of circular cross section, with specified elevated temperature properties, made of non-alloy and alloy steel.

该文件规定了由非合金钢和合金钢制成的具有指定高温性能的圆形横截面无缝管的两个试验类别的技术交付条件。

DIN EN 10216-3

Seamless steel tubes for pressure purposes -Technical delivery conditions - Part 3: Alloy fine grain steel tubes

压力用无缝钢管交货技术条件第3部分:合金细晶粒钢管

Specifies the technical delivery conditions in two categories for seamless tubes of circular cross section, made of weldable alloy fine grain steel

规定了由可焊接合金细晶粒钢制成的圆形横截面无缝管的两类交货技术条件

DIN EN 10216-4

Seamless steel tubes for pressure purposes - Technical delivery conditions -Part 4: Non-alloy and alloy steel tubes with specified low temperature properties

压力用无缝钢管.交货技术条件.第4部分:具有规定低温性能的非合金和合金钢管

Specifies the technical delivery conditionsin two categories for seamless tubes of circular crossection, made with specified low temperature properties, made of non-alloy and alloy steel.

规定了圆形横截面无缝管的两类技术交付条件,这些无缝管具有指定的低温性能,由非合金钢和合金钢制成。

DIN EN 10216-5

Seamless steel tubes for pressure purposes - Technical delivery conditions-Part 5: Stainless steel tubes; German version EN 10216-5:2004, Corrigendum to DIN EN 10216-5:2004-11; German version EN 10216-5:2004/AC:2008

压力用无缝钢管.交货技术条件.第5部分:不锈钢管;德文版EN 10216-5:2004,对DIN EN 10216-5.2004-11的更正;德文版EN 10216-5:2004/AC:2008

This Part of this European Standard specifies the technical delivery conditions in two test categories for seamless tubes of circular cross-section made of austenitic (including creep resisting steels) and austenitic-ferritic stainless steel which are applied for pressure and corrosion resisting purposes at room temperature, at low temperatures or at elevated temperatures. It is important that the purchaser, at the time of enquiry and order, takes in account the requirements of the relevant national legal regulations for the intended application.

本部分欧洲标准规定了奥氏体(包括抗蠕变钢)和奥氏体-铁素体不锈钢制成的圆形横截面无缝管的两个试验类别的技术交付条件,这些无缝管用于室温、低温或高温下的耐压和耐腐蚀目的。重要的是,买方在询价和订购时,要考虑到相关国家法律法规对预期应用的要求。

What Is Non Alloy Steel?什么是非合金钢?

Steel is common called carbon steel because of the mixture of carbon atoms with iron atoms. The added elements provide the steel with ductility and strength. During the smelting process, other elements, such as aluminum is added to the steel making it an alloy steel. Non-alloy steel has no elements added to the steel as it is smelted.

钢通常被称为碳钢,因为它是碳原子和铁原子的混合物。添加的元素为钢提供了延展性和强度。在冶炼过程中,其他元素,如铝,被添加到钢中,使其成为合金钢。非合金钢在冶炼过程中没有添加任何元素。

Manufacturing制造业

The manufacturing of steel is done by placing ore in a furnace a smelting the ore. The smelting process removes any impurities in the iron ore. Once the first smelting process is performed, the steel still has too much carbon content to become non-alloy steel. The smelting process is performed again and again until the carbon content in the ore falls below 1.5 percent of the total content.

钢的制造是通过将矿石放入炉中冶炼矿石来完成的。冶炼过程会去除铁矿石中的任何杂质。一旦进行了第一次冶炼过程,钢的碳含量仍然太高,无法成为非合金钢。冶炼过程一次又一次地进行,直到矿石中的碳含量降至总含量的1.5%以下。

Smelting冶炼

The smelting process melts the iron ore. By melting the ore, the extraction of elements and impurities can be accomplished. The manufacturer only wants the iron and a small amount of carbon from the ore to make non-alloy steel.

冶炼过程熔化铁矿石。通过熔化矿石,可以完成元素和杂质的提取。制造商只希望从矿石中提取铁和少量碳来制造非合金钢。在冶炼过程中,钴、铜和铝等元素被添加到矿石中,使钢成为合金钢。During the smelting process, elements get added to the ore such as cobalt, copper and aluminum, which makes the steel an alloy steel. Non-alloy steel has no other elements added to the iron and carbon during the smelting process.

非合金钢在冶炼过程中没有其他元素添加到铁和碳中。

Tempering回火

The non-alloy steel must be tempered at a certain temperature because it does not use other elements to make it flexible and durable. Tempering non-alloy steel at a certain temperature make the steel more sensitive to cracking when being welded.

非合金钢必须在一定温度下回火,因为它不使用其他元素使其灵活耐用。在一定温度下回火非合金钢会使钢在焊接时更容易开裂。

Applications应用

Non-alloy steel can be used for different applications. Steel bars used to strengthen concrete is a non-alloy steel. Wrought iron is another non-alloy steel because it has little to no carbon within the iron ore. The wrought iron is soft and easily workable into different shapes but has very little strength. Non-alloy steel is often used to make decorative metal gates and fences.

非合金钢可用于不同的应用。用于加固混凝土的钢筋是一种非合金钢。锻铁是另一种非合金钢,因为它在铁矿石中几乎不含碳。锻铁很软,很容易加工成不同的形状,但强度很小。非合金钢通常用于制作装饰性金属门和围栏。

Related EN 10216相关EN 10216

- EN 10216-1 non alloy steel tubes·EN 10216-1非合金钢管

- EN 10216-2 Seamless steel tubes·EN 10216-2无缝钢管

- EN 10216-2 16Mo3 Seamless Carbon Steel Pipe·EN 10216-2 16Mo3无缝碳钢管

- EN 10216-2 P265GH Seamless Carbon Steel Tube·EN 10216-2 P265GH无缝碳钢管

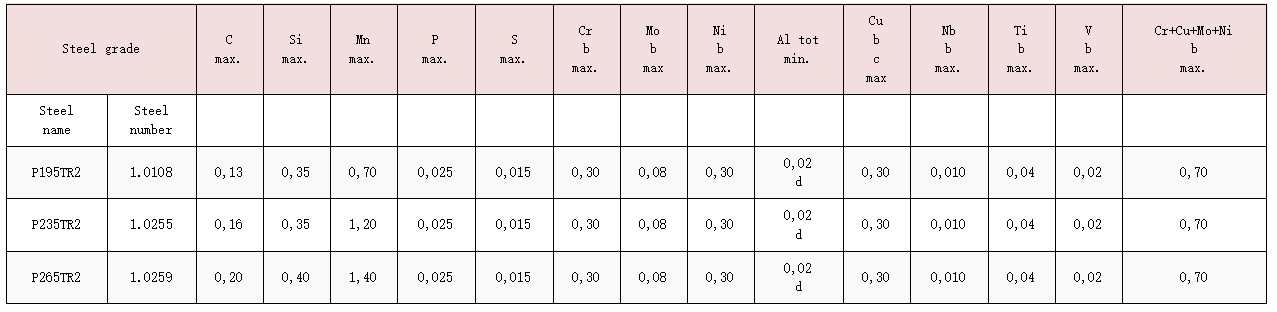

Table 2 — Chemical composition (cast analysis) a in % by mass for quality TR2表2--质量TR2的化学成分(铸件分析)a质量百分比

a Elements not included in this Table shall not be intentionally added to the steel without the agreement of the purchaser, except for elements which may be added for finishing the cast. All appropriate measures shall be taken to prevent the addition of undesirable elements from scrap or other materials used in the steelmaking process.

a未经买方同意,不得有意将本表中未包含的元素添加到钢中,但为完成铸件而添加的元素除外。应采取一切适当措施,防止在炼钢过程中使用的废料或其他材料中添加不需要的元素。

b The content of these elements need not be reported unless intentionally added to the cast.

b除非有意添加到铸件中,否则不需要报告这些元素的含量。

c Option 2: In order to facilitate subsequent forming operation, an agreed maximum copper content lower than indicated and an agreed specified maximum tin content shall apply.

c选项2:为了便于后续成型操作,应采用低于指示的商定最大铜含量和商定的规定最大锡含量。

d This requirement is not applicable provided the steel contains a sufficient amount of other nitrogen binding elements which shall be reported.

d如果钢中含有足够量的其他氮结合元素,则此要求不适用,应予以报告。

Table 3 —Chemical composition (cast analysis) a in % by mass for quality TR1

表3--质量TR1的化学成分(铸件分析)a质量百分比

a Elements not included in this table shall not be intentionally added to the steel without the agreement of the purchaser, except for elements which may be added for finishing the cast. All appropriate measures shall be taken to prevent the addition of undesirable elements from scrap or other materials used in the steelmaking process.

a未经买方同意,不得有意将本表中未包含的元素添加到钢中,但为完成铸件而添加的元素除外。应采取一切适当措施,防止在炼钢过程中使用的废料或其他材料中添加不需要的元素。

b The content of these elements need not be reported unless intentionally added to the cast.

b除非有意添加到铸件中,否则不需要报告这些元素的含量。

c Option 2:In order to facilitate subsequent forming operation, an agreed maximum copper content lower than indicated and an agreed specified maximum tin content shall apply.

c选项2:为了便于后续成型操作,应采用低于指示的商定最大铜含量和商定的规定最大锡含量。

d These grades do not support the Essential Requirements of the New Approach Directive 97/23/EC.

d这些等级不符合新方法指令97/23/EC的基本要求。

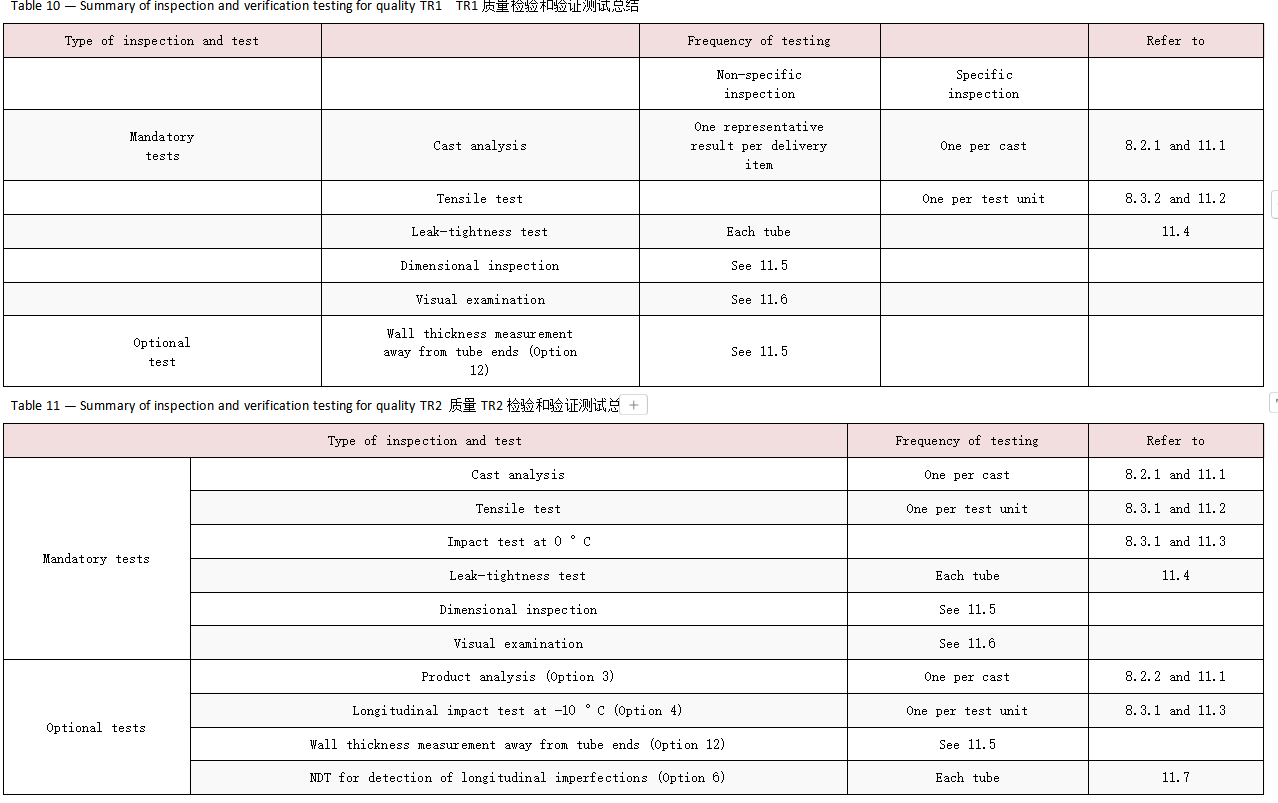

8.2.2 Product analysis产品分析

Option 3: A product analysis for tubes of quality TR2 shall be supplied. For tubes with outside diameter less than or equal to 76, 1 mm this option applies only in combination with Option 11.

选项3:应提供TR2质量管的产品分析。对于外径小于或等于76、1 mm的管子,此选项仅与选项11结合使用。

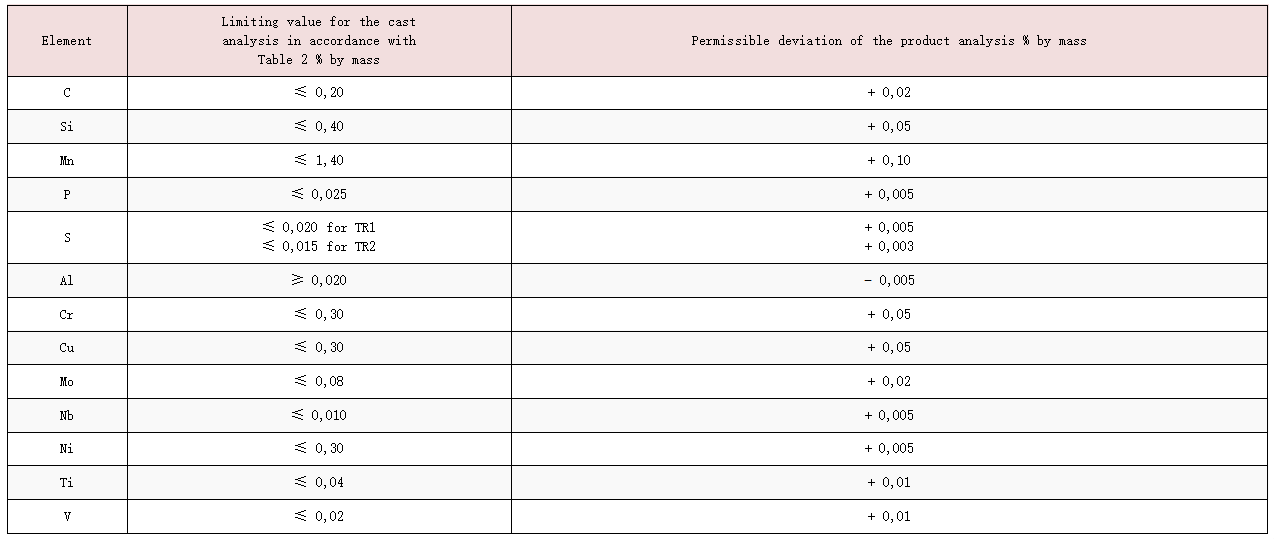

Table 4 specifies the permissible deviations of the product analysis from the specified limits on cast analysis given in Table 2 and Table 3.

表4规定了产品分析与表2和表3中给出的铸件分析规定限值的允许偏差。

Table 4 —Permissible deviations of the product analysis from specified limits on cast analysis given in Tables 2 and 3

表4——产品分析与表2和表3中给出的铸件分析规定限值的允许偏差

8.3 Mechanical properties机械性能

8.3.1 Mechanical properties for quality TR2质量TR2的机械性能

The mechanical properties of the tubes shall conform to the requirements of Table 5 for grade TR2 irrespective of whether they are verified or not (see Table 11).

管子的机械性能应符合表5中TR2级的要求,无论是否经过验证(见表11)。

Table 5 — Mechanical properties for quality TR2 a质量TR2 a的机械性能

a For wall thickness greater than 60 mm the mechanical properties are subject to agreement.a对于大于60mm的壁厚,机械性能须经双方同意。

b See 11.2.

c l = longitudinal t = transverse c l=纵向t=横向

d Option 4: In addition to the test in Table 11, longitudinal impact strength shall be verified at - 10 °C.

d选项4:除表11中的试验外,还应在-10°C下验证纵向冲击强度。

*1 MPa = 1 N/mm 2

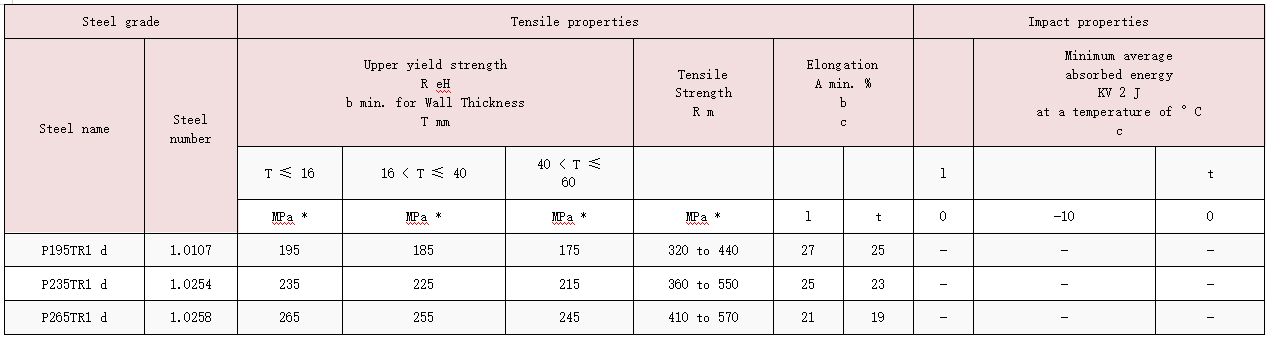

8.3.2 Mechanical properties for quality TR1质量TR1的机械性能

The mechanical properties of the tubes shall conform to the requirements of Table 6 for grade TR1 irrespective of whether they are verified or not (see Table 10).

管子的机械性能应符合表6中TR1级的要求,无论是否经过验证(见表10)。

Table 6 — Mechanical properties for quality TR1 a TR1 a质量的机械性能

a For wall thickness greater than 60 mm the mechanical properties are subject to agreement.a对于大于60mm的壁厚,机械性能须经双方同意。

b See 11.2.

c l = longitudinal t = transverse c l=纵向t=横向

d These grades do not support the Essential Requirements of the New Approach Directive 97/23/EC.

d这些等级不符合新方法指令97/23/EC的基本要求。

* 1 MPa = 1 N/mm

8.4 Appearance and internal soundness外观和内部坚固性

8.4.1 Appearance外貌

8.4.1.1 The tubes shall be free from external and internal surface defects that can be detected by visual examination.管子应无肉眼可见的内外表面缺陷。

8.4.1.2 The internal and external surface finish of the tubes shall be typical of the manufacturing process and,where applicable, the heat treatment employed. Normally the finish and surface condition shall be such that any surface imperfections requiring dressing can be identified.管子的内外表面光洁度应符合制造工艺的典型要求,并在适用的情况下采用热处理。通常,表面光洁度和表面状况应能识别出任何需要修整的表面缺陷。

8.4.1.3 It shall be permissible to dress, only by grinding or machining, surface imperfections provided that,after doing so, the wall thickness in the dressed area is not less than the specified minimum wall thickness. All dressed areas shall blend smoothly into the contour of the tube.仅允许通过研磨或机加工来修整表面缺陷,前提是修整后,修整区域的壁厚不小于规定的最小壁厚。所有修整区域应平滑地融入管道轮廓。

8.4.1.4 Surface imperfections which encroach on the specified minimum wall thickness shall be considered defects and tubes containing these shall be deemed not to conform to this Part of this EN 10216.

侵犯规定最小壁厚的表面缺陷应被视为缺陷,含有这些缺陷的管子应被视不符合本EN 10216的本部分。

8.4.2 Internal soundness内部稳健性

8.4.2.1 Leak-tightness密封性

The tubes shall pass a hydrostatic test (see 11.4.1) or electromagnetic test (see 11.4.2) for leak-tightness.Unless the Option 5 is specified the choice of the test method is at the discretion of the manufacturer.

管子应通过水压试验(见11.4.1)或电磁试验(见114.2)进行密封性测试。除非指定了选项5,否则测试方法的选择由制造商自行决定。

Option 5: The test method for verification of leak-tightness in accordance with 11.4.1 or 11.4.2 is specified by the purchaser.

选项5:买方规定了根据11.4.1或11.4.2验证密封性的试验方法。

8.4.2.2 Non-Destructive Testing无损检测

Option 6: The tubes of quality TR2 shall pass a non-destructive test for the detection of longitudinal imperfections in accordance with 11.7. The test method shall be specified by the purchaser

选项6:根据11.7,质量为TR2的管子应通过无损检测,以检测纵向缺陷。试验方法应由买方指定

8.5 Straightness直线度

The deviation from straightness, of any tube length L shall not exceed 0,001 5 L. Deviations from straightness over any one metre length shall not exceed 3 mm.

任何管长L的直线度偏差不得超过0001 5 L。任何一米长度的直线度误差不得超过3 mm。

8.6 Preparation of ends末端准备

Tubes with wall thickness ≥ 3,2 mm shall be delivered with square cut ends. The ends shall be free from excessive burrs.壁厚≥3.2mm的管子应交付方形切割端。端部应无过多毛刺。

Option 7: The tubes with wall thickness ≥ 3.2 mm shall be delivered with bevelled ends (see Figure 1). The bevel shall have an angle α of 30°( +°5,-0°)with a root face C of 1,6 mm ± 0,8 mm, except that for wall thickness T greater than 20 mm, an agreed alternative bevel may be specified.

选项7:壁厚≥3.2mm的管子应交付斜切端(见图1)。斜面的角度α应为30°(+°5,-0°),根部面C为1.6 mm±0.8 mm,但壁厚T大于20 mm的情况除外,可以指定商定的替代斜面。

Key

D outside diameter

α bevel angle

C root face of bevelled end

Figure 1 — Tube end beve

8.7 Dimensions, masses and tolerances尺寸、质量和公差

8.7.1 Diameter and wall thickness直径和壁厚

Tubes shall be delivered by outside diameter D and wall thickness T.管子应按外径D和壁厚T交付。

Preferred outside diameters D and wall thicknesses T have been selected from EN 10220 and are given in Table 7.

优选的外径D和壁厚T已从EN 10220中选择,并在表7中给出。

Dimensions which are different from those in Table 7 may be agreed.与表7中不同的尺寸可以达成一致。

8.7.2 Mass质量

For the mass per unit length the provisions of EN 10220 apply.对于单位长度的质量,EN 10220的规定适用。

8.7.3 Lengths长度

Unless Option 8 is specified the tubes are delivered in random lengths. The delivery range shall be agreed at the time of enquiry and order.

除非指定了选项8,否则管道的交付长度是随机的。交货范围应在询价和订购时商定。

Option 8: The tubes shall be delivered in exact lengths and the length shall be specified at the time of enquiry and order. For the tolerances, see 8.7.4.2.l

选项8:管子应按精确长度交付,长度应在询价和订购时指定。公差见8.7.4.2.l

Table 7 — Preferred dimensions

Dimensions in millimetres

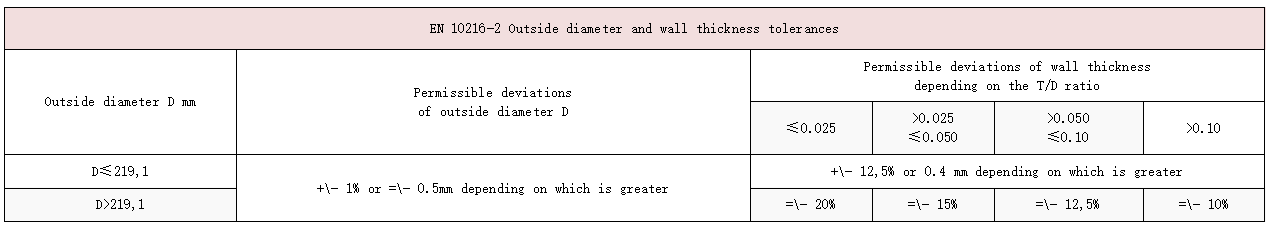

8.7.4 Tolerances公差

8.7.4.1 Tolerances on diameter and thickness直径和厚度公差

The diameter and the wall thickness of the tubes shall be within the tolerance limits given in Table 8.管子的直径和壁厚应在表8给出的公差范围内。

Out-of-roundness is included in the tolerances on outside diameter and eccentricity is included in the tolerances on wall thickness.

不圆度包含在外径公差中,偏心度包含在壁厚公差中。

Table 8 — Tolerances on outside diameter and on wall thickness外径和壁厚公差

|

Outside |

Tolerances on D |

Tolerances on T for a T/D ratio |

|||

|

|

|

≤ 0,025 |

> 0,025 |

> 0,050 |

> 0,10 |

|

D ≤ 219,1 |

± 1% or ± 0,5 mm whichever is the greater |

± 12,5 % or ± 0,4 mm |

|||

|

D > 219,1 |

|

± 20 % |

± 15 % |

± 12,5 % |

± 10 % a |

a For outside diameters D ≥ 355,6 mm it is permitted to exceed the upper wall thickness locally by a further 5 % of the wall thickness T

a对于外径D≥355,6 mm,允许局部超过上壁厚5%的壁厚T

8.7.4.2 Tolerances on exact lengths精确长度公差

The tolerances for exact lengths shall be as given in Table 9.精确长度的公差应如表9所示。

Table 9 — Tolerances on exact lengths精确长度公差

Dimensions in millimetres尺寸单位为毫米

|

Length L |

Tolerance on exact length |

|

L ≤ 6 000 |

+ 10 |

|

6 000 < L ≤ 12 000 |

+15 |

|

L > 12 000 |

+by agreement |

9 Inspection检查

9.1 Types of inspection检查类型

Conformity to the requirements of the order, for tubes in accordance with this Part of EN 10216, shall be verified by:

对于符合EN 10216本部分的管子,应通过以下方式验证其是否符合订单要求:

non-specific or specific inspection for quality TR1;

TR1的非特定或特定质量检查;

specific inspection for quality TR2.

TR2质量专项检查。

When an inspection certificate 3.1 is specified, the material manufacturer shall state in the confirmation of the order whether he is operating according to a “quality-assurance system”, certified by a competent Body established within the Community, and having undergone a specific assessment for materials.

当指定了检验证书3.1时,材料制造商应在订单确认书中说明其是否按照“质量保证体系”运行,该体系由共同体内设立的主管机构认证,并已对材料进行了具体评估。

NOTE See the EU Directive 97/23/EC, Annex I, section 4.3 third paragraph and for further information the Guidelines of the EU Commission and the Member States for its interpretation (see e.g. Guidelines 7/2 and 7/16).

注:见欧盟指令97/23/EC,附件一,第4.3节第三段,更多信息见欧盟委员会和成员国的指南(例如,见指南7/2和7/16)。

9.2 Inspection documents检验文件

9.2.1 Types of inspection documents检验文件类型

The following inspection documents, in accordance with EN 10204, shall be issued;应根据EN 10204发布以下检验文件;

- test report 2.2 for quality TR1;-TR1质量测试报告2.2;

- inspection certificate 3.1 for quality TR2.-质量检验证书3.1 TR2。

Option 9: One of the following inspection documents, specified by the purchaser, shall be issued:

选项9:应出具买方指定的以下检验文件之一:

- for quality TR1 specific inspection with inspection certificate 3.2;

-用于质量TR1特定检查,并附有检验证书3.2;

- for quality TR2, an inspection certificate 3.2.

-对于质量TR2,检验证书为3.2。

If an inspection certificate 3.2 is specified, the purchaser shall notify the manufacturer of the name and address of the organization or person who is to carry out the inspection and produce the inspection document, and it shall be agreed which party shall issue the certificate.

如果规定了检验证书3.2,买方应通知制造商进行检验并出示检验文件的组织或人员的名称和地址,并应商定由哪一方颁发证书。

Document 3.1 and 3.2 are to be validated by the manufacturer’s authorized representative.

文件3.1和3.2应由制造商授权代表验证。

9.2.2 Content of inspection documents

9.2.2检验文件内容

9.2.2.1 The content of the inspection document shall be in accordance with EN 10168 as shown in 9.2.2.2 and9.2.2.3.

9.2.2.1检验文件的内容应符合EN 10168,如9.2.2.2和9.2.2.3所示。

In all types of inspection documents, a statement on the conformity of the products delivered with the requirements of this specification and the order shall be included.

在所有类型的检验文件中,应包括一份关于交付产品符合本规范和订单要求的声明。

9.2.2.2 For tubes supplied with non-specific inspection, the test report shall contain the following codes and information:

9.2.2.2对于提供非特定检验的管子,试验报告应包含以下代码和信息:

A commercial transactions and parties involved; 商业交易及其涉及的各方;

B description of products to which the inspection document applies;检验文件适用的产品说明;

C02 direction of test pieces; C02试样方向;

C10–C13 tensile test; C10-C13拉伸试验;

C71–C92 chemical composition; C71-C92化学成分;

D01 marking and identification, surface appearance, shape and dimensional properties; D01标记和标识、表面外观、形状和尺寸特性;

D02–D99 leak-tightness test; D02-D99密封性试验;

Z validation.验证。

9.2.2.3 For tubes supplied with specific inspection the inspection certificate shall contain the following codes and information:

9.2.2.3对于经过特定检验的管子,检验证书应包含以下代码和信息:

A commercial transactions and parties involved; 商业交易及其涉及的各方;

B description of products to which the inspection document applies 检验文件适用的产品说明

C02–C03 direction of test pieces and testing temperature; C02-C03试样方向和试验温度;

C10–C13 tensile test; C10-C13拉伸试验;

C40–C43 impact test, if applicable; C40-C43冲击试验(如适用);

C71–C92 chemical composition on cast analysis (product analysis if applicable); C71-C92铸件化学成分分析(如适用,进行产品分析);

D01 marking and identification, surface appearance, shape and dimensional properties; D01标记和标识、表面外观、形状和尺寸特性;

D02–D99 leak-tightness test; NDT if applicable; D02-D99密封性试验;无损检测(如适用);

Z validation.验证。

In addition, for inspection document 3.1 the manufacturer shall state the references to the certificate (see 9.1) of the appropriate “quality-assurance system“, if applicable

此外,对于检验文件3.1,制造商应说明适当的“质量保证体系”证书(见9.1)的参考(如适用)

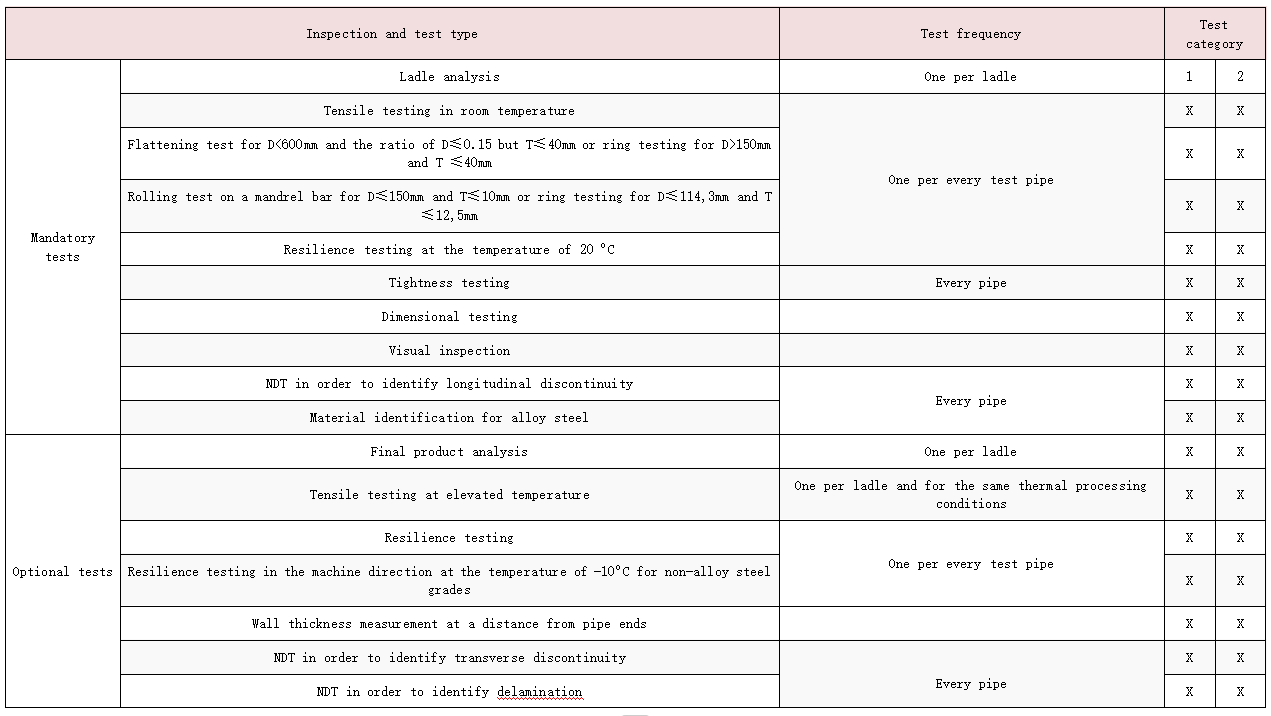

9.3 Summary of inspection and verification testing检验和验证测试总结

10 Sampling取样

10.1 Frequency of tests测试频率

10.1.1 Test unit测试单元

In case of specific inspection, a test unit shall comprise:在特定检查的情况下,测试单元应包括:

Quality TR1: Tubes of the same specified outside diameter and wall thickness, the same steel grade, the same manufacturing process and, if applicable, the same normalising treatment in a continuous furnace or heat-treated in the same furnace charge in a batch-type furnace.

质量TR1:具有相同规定外径和壁厚、相同钢种、相同制造工艺的管子,如果适用,在连续炉中进行相同的正火处理,或在间歇式炉中在相同炉料中进行热处理。

Quality TR2: Tubes of the same specified outside diameter and wall thickness, the same steel grade, the same cast, the same manufacturing process and, if applicable, the same normalising treatment in a continuous furnace or heat-treated in the same furnace charge in a batch-type furnace. Tubes with specified outside diameter less than or equal to 76.1 mm need not be separated by cast unless Option 10 is specified.

质量TR2:具有相同规定外径和壁厚、相同钢号、相同铸件、相同制造工艺的管子,如果适用,在连续炉中进行相同的正火处理,或在间歇式炉中在相同炉料中进行热处理。除非指定了选项10,否则指定外径小于或等于76.1mm的管子不需要通过铸造分开。

The number of tubes, in manufacturing lengths, per test unit shall conform to Table 12. 每个试验单元的管子数量(以制造长度计)应符合表12。

The manufacturing length (e.g. the rolled length after the normalising forming process) may differ from the delivery length providing there is no additional HT after cutting the manufacturing lengths into individual lengths.

Option 10: Tubes with specified outside diameter less than or equal to 76,1 mm shall be separated by cast for quality TR2 .

制造长度(例如正火成形工艺后的轧制长度)可能与交付长度不同,前提是在将制造长度切割成单个长度后没有额外的HT。

选项10:规定外径小于或等于76,1 mm的管子应通过铸件隔开,以获得TR2质量。

Table 12 — Number of tubes per test unit每个测试单元的试管数量

|

Outside diameter D(mm) |

Maximum number of tubes per test unit |

|

|

Quality TR1 |

Quality TR2 |

|

|

D ≤ 114,3 |

400 |

200 |

|

114,3 < D ≤ 323,9 |

200 |

100 |

|

D > 323,9 |

100 |

50 |

10.1.2 Number of sample tubes per test unit每个测试单元的样品管数量

One sample tube shall be taken from each test unit.每个测试单元应取一个样品管。

10.2 Preparation of samples and test pieces样品和试样的制备

10.2.1 Selection and preparation of samples for product analysis Samples for product analysis shall be taken from the test pieces or samples for mechanical testing or from the whole thickness of the tube at the same location as the mechanical test samples, in accordance with EN ISO 14284.

10.2.1产品分析样品的选择和制备根据EN ISO 14284,产品分析样品应从机械测试的试样或样品中取出,或从与机械测试样品相同位置的整个管子厚度中取出。

10.2.2 Location, orientation and preparation of samples and test pieces for mechanical tests机械试验样品和试件的位置、方向和制备

10.2.2.1 General概述

Samples and test pieces shall be taken at the tube ends and in accordance with the requirements of EN ISO 377.应按照EN ISO 377的要求在管端取样和试件。

10.2.2.2 Test pieces for tensile test拉伸试验用试样

The test pieces for tensile test shall be prepared in accordance with EN ISO 6892-1.拉伸试验的试样应按照EN ISO 6892-1制备。

At the manufacturer's discretion:制造商可自行决定:

for tubes with an outside diameter D ≤ 219,1 mm the test piece shall be either a full tube section or a strip section and shall be taken in a direction longitudinal to the axis of the tube;

对于外径D≤219.1 mm的管子,试样应为全管段或条形段,并应沿管子轴线的纵向截取;

for tubes with an outside diameter D > 219,1 mm the test piece shall either a machined test piece with circular cross section from an unflattened sample or a strip section and be taken in a direction either longitudinal or transverse to the axis of the tube.

对于外径D>219.1 mm的管子,试件应为未抛光样品或条形截面的圆形横截面机加工试件,并沿管子轴线的纵向或横向取样。

10.2.2.3 Test pieces for impact test冲击试验试样

Three standard Charpy V-notch test pieces shall be prepared in accordance with EN ISO 148-1. If the wall thickness is such that standard test pieces cannot be produced without flattening of the section, then test pieces of width less than 10 mm, but not less than 5 mm shall be prepared; the largest obtainable width shall be used.

应按照EN ISO 148-1制备三个标准夏比V型缺口试样。如果壁厚使得在不压平截面的情况下无法生产标准试件,则应准备宽度小于10mm但不小于5mm的试件;应使用可获得的最大宽度。

Where test pieces at least 5 mm width cannot be obtained, the tubes shall not be subjected to impact testing.如果无法获得至少5mm宽的试样,则不得对管子进行冲击试验。

Unless otherwise specified (see Option 4), the test pieces shall be taken transverse to the tube axis unless D min , as calculated by the following equation, is greater than the specified outside diameter, in which case longitudinal test pieces shall be used:

除非另有规定(见选项4),否则应横向于管轴取试样,除非由以下方程式计算的D min大于规定的外径,在这种情况下,应使用纵向试样:

D min = (T-5) + [ 756,25 / (T-5) ] (1)

The test pieces shall be prepared such that the axis of the notch is perpendicular to the surface of the tube,see Figure 2.

试样的制备应使缺口轴线垂直于管表面,见图2。

Key

1 longitudinal test piece

2 transverse test piece

w specimen width

Figure 2 — Impact test piece orientation

11 Verification test methods验证试验方法

11.1 Chemical analysis化学分析

The elements to be determined and reported shall be those specified in Table 2. The choice of a suitable physical or chemical analytical method for the analysis shall be at the discretion of the manufacturer. In cases of dispute, the method used shall be agreed between manufacturer and purchaser taking into account CEN/TR 10261.

待确定和报告的元素应为表2中规定的元素。制造商应自行决定选择合适的物理或化学分析方法进行分析。如有争议,制造商和买方应考虑CEN/TR 10261,就使用的方法达成一致。

11.2 Tensile test拉伸试验

The test shall be carried out at room temperature in accordance with EN ISO 6892-1, and the following shall be determined:

应按照EN ISO 6892-1在室温下进行试验,并应确定以下内容:

the tensile strength (R m );抗拉强度(Rm);

the upper yield strength (R eH ) or if a yield phenomenon is not present the 0,2 % proof strength (R p0,2 );屈服强度上限(R eH),或者如果不存在屈服现象,则为0.2%的屈服强度(R p0,2);

the percentage elongation after fracture with a reference to a gauge length ( L 0 ) of So ⋅ 65 , 5 ; if a nonproportional test piece is used, the percentage elongation value shall be converted to the value for a gauge length So Lo ⋅ = 65 , 5 using the conversion tables in EN ISO 2566-1.断裂后相对于标距长度(L 0)的伸长率为So⋅65,5;如果使用非比例试样,则应使用EN ISO 2566-1中的转换表将伸长率值转换为标距长度So Lo⋅=65,5的值。

11.3 Impact test冲击试验

11.3.1 The test shall be carried out (but see 10.2.2.3) in accordance with EN ISO 148-1 at 0 °C and, if option 4 is specified, at -10 °C.

应按照EN ISO 148-1在0°C下进行测试(但见10.2.2.3),如果指定了选项4,则应在-10°C下。

11.3.2 The mean value of the three test pieces shall meet the requirements given in Table 5 and Table 6. One individual value may be below the specified value, provided that it is not less than 70 % of that value.

11.3.2三个试样的平均值应符合表5和表6的要求。一个单独的值可能低于指定值,前提是它不小于该值的70%。

11.3.3 If the width (W) of the test piece is less than 10 mm, the measured impact energy (KV p ) shall be converted to the calculated impact energy( KV c ) using the following equation:

11.3.3如果试件的宽度(W)小于10 mm,则应使用以下方程式将测量的冲击能量(KV p)转换为计算的碰撞能量(KV c):

where

KV c is the calculated impact energy, in joules; KV c是计算出的冲击能量,单位为焦耳;

KV p is the measured impact energy, in joules; KV p是测量的冲击能量,单位为焦耳;

W is the width of the test piece, in millimetres. W是试样的宽度,单位为毫米。

The calculated impact energy KV c shall conform to the requirements given in 11.3.2. 计算出的冲击能量KV c应符合11.3.2中给出的要求。

11.3.4 If the requirements of 11.3.2 are not met, then an additional set of three test pieces may be taken at the discretion of the manufacturer from the same sample and tested. To consider the test unit as conforming, after testing the second set, the following conditions shall be satisfied simultaneously:

11.3.4如果不符合11.3.2的要求,则制造商可自行决定从同一样品中额外取三个试样进行测试。为了认为测试单元合格,在测试第二组后,应同时满足以下条件:

the average value of the six tests shall be equal to or greater than the specified minimum value;

六次试验的平均值应等于或大于规定的最小值;

not more than two of the six individual values may be lower than the specified minimum value;

六个单独值中不超过两个可能低于指定的最小值;

not more than one of the six individual values may be lower than 70 % of the specified minimum average value.

六个单独值中不超过一个可以低于指定最小平均值的70%。

11.3.5 The dimensions in millimetres of the test pieces, the measured impact energy values and the resulting average value shall be reported.

11.3.5应报告试样的尺寸(单位:毫米)、测量的冲击能量值和由此产生的平均值。

11.4 Leak tightness test密封性试验

11.4.1 Hydrostatic test水压试验

The hydrostatic test shall be carried out at a test pressure of 70 bar 1) or at a test pressure P calculated using the following equation, whichever is lower:

静水压试验应在70 bar 1)的试验压力或使用以下方程式计算的试验压力P下进行,以较低者为准:

where

P is the test pressure, in bar;P是试验压力,单位为bar;

D is the specified outside diameter, in millimetres;D为规定外径,单位为毫米;

T is the specified wall thickness, in millimetres;T是规定的壁厚,单位为毫米;

S is the stress, in MPa, corresponding to 70 % of the specified minimum yield strength (see Table 5 and Table 6) for the steel grade concerned.

S是对应于相关钢种规定最小屈服强度(见表5和表6)70%的应力,单位为MPa。

The test pressure shall be held for not less than 5 s for tubes with an outside diameter D less than or equal to 457 mm and for not less than 10 s for tubes with an outside diameter D greater than 457 mm.

对于外径D小于或等于457 mm的管子,试验压力应保持不少于5 s,对于外径D大于457 mm的管,试验压力保持不少于10 s。

The tube shall withstand the test without showing leakage.管子应能承受试验,而不会出现泄漏。

NOTE This hydrostatic leak-tightness test is not a strength test.注:此静水压密封性试验不是强度试验。

11.4.2 Electromagnetic test电磁试验

The test shall be carried out in accordance with EN ISO 10893-1.试验应按照EN ISO 10893-1进行。

11.5 Dimensional inspection尺寸检查

Specified dimensions, including straightness, shall be verified.应验证规定的尺寸,包括直线度。

The outside diameter shall be measured at tube ends. For tubes with outside diameter D ≥ 406,4 mm, the diameter may be measured using a circumference tape.

外径应在管端测量。对于外径D≥406.4mm的管子,可以使用周长带测量直径。

Unless Option 11 is specified the wall thickness shall be measured at both tube ends.

除非指定了选项11,否则应在管两端测量壁厚。

Option 11: The wall thickness shall be measured away from the tube ends in accordance with an agreed procedure.

选项11:应按照商定的程序在远离管端的地方测量壁厚。

11.6 Visual examination目视检查

Tubes shall be visually examined to ensure conformity to the requirements of 8.4.1.

应对管子进行目视检查,以确保符合8.4.1的要求。

11.7 Non-Destructive Testing无损检测

When Option 6 is specified, the tubes of quality TR2 shall be subjected to Non-Destructive testing for the detection of longitudinal imperfections in accordance with EN ISO 10893-2, EN ISO 10893-3 or EN ISO 10893-10 to acceptance level 3, sub-category C, where applicable.

当指定选项6时,应根据EN ISO 10893-2、EN ISO 10893-3或EN ISO 108933-10对质量为TR2的管子进行无损检测,以检测纵向缺陷,达到验收等级3,子类别C(如适用)。

Regions at the tube ends not automatically tested shall either be subjected to manual/semi-automatic ultrasonic testing in accordance with EN ISO 10893-10 or be cropped off.

未自动测试的管端区域应按照EN ISO 10893-10进行手动/半自动超声波测试,或进行裁剪。

11.8 Retest, sorting and reprocessing重新测试、分类和再处理

For retest, sorting and reprocessing the requirements of EN 10021 shall apply.

对于重新测试、分类和再处理,应适用EN 10021的要求。

12 Marking标记

12.1 Marking to be applied待应用的标记

The marking shall be indelibly marked on each tube at least at one end. For tubes with outside diameter D ≤ 51 mm the marking on tubes may be replaced by the marking on a label attached to the bundle or box.

标记应至少在一端永久标记在每根管子上。对于外径D≤51 mm的管子,管子上的标记可以用捆绑或箱子上的标签上的标记代替。

The marking shall include the following information:

标记应包括以下信息:

the manufacturer's name or trade mark;

制造商名称或商标;

the number of this European Standard and the steel name (see 5.2).

本欧洲标准的编号和钢材名称(见5.2)。

In addition in case of specific inspection:此外,在具体检查的情况下:

the cast number or a code number; 铸造编号或代码编号;

the mark of the inspection representative; 检验代表的标记;

an identification number (e.g. order or item number), which permit the correlation of the product or delivery unit to related documents.

标识号(例如订单或项目号),允许将产品或交付单元与相关文件相关联。

Example of marking:标记示例:

EXAMPLE X – EN 10216-1 - P265TR2 - Y - Z 1 - Z 2示例X-EN 10216-1-P265TR2-Y-Z 1-Z 2

where

X is the manufacturer's mark;X是制造商的标志;

Y is the cast number or the code number;Y是铸造编号或代码编号;

Z 1 is the mark of the inspection representative;Z 1是检验代表的标志;

Z 2 is the identification number.Z 2是识别号。

12.2 Additional marking附加标记

Option 12: Additional marking, as agreed upon at the time of the enquiry and order, shall be applied.

选项12:应采用询价和订购时商定的额外标记。

13 Protection保护

The tubes shall be delivered without a temporary protective coating.交付的管子应无临时保护涂层。

Option 13: A temporary protective coating or durable coating and/or lining shall be applied.

选项13:应涂覆临时保护涂层或耐用涂层和/或衬里。

Inspection and Test For EN 10216-2 Steel Pipe EN 10216-2钢管的检验和测试

Dimension for EN10216-2 Steel pipe EN10216-2钢管尺寸

For the outside diameter of D≥355,6 mm, local deviation outside of the upper deviation limit by further 5% of the wall thickness T is permitted

对于外径D≥355,6mm的情况,允许局部偏差超出偏差上限5%的壁厚T

扫二维码用手机看

- 联系电话- 0317-6689999 6165555

- 业务邮箱- 9905791@qq.com

- 公司地址- 河北省沧州市盐山县千童大街沧州银行对面

- 联系电话- 0317-6689999 6165555

- 业务邮箱- 9905791@qq.com

- 公司地址- 河北省沧州市盐山县千童大街沧州银行对面

版权所有:英国ladbrokes官方网站 冀ICP备19004948号-6

热线:0317-6165555

热线:0317-6165555 9905791@qq.com

9905791@qq.com