ASTM A213/A213M无缝铁素体和奥氏体合金钢锅炉、过热器和换热器管标准规范

- 分类:国外产品技术与服务

- 作者:www.negerekli.com中燃管道

- 来源:英国ladbrokes官方网站

- 发布时间:2024-09-24

- 访问量:82

【概要描述】ASTM A213/A213M规范涵盖了无缝铁素体和奥氏体钢锅炉、过热器和换热器管。在其名称中包含字母H的等级的要求与不含字母H的类似等级的要求不同。这些不同的要求提供了比没有这些不同要求的类似等级通常可达到的更高的蠕变断裂强度。

ASTM A213/A213M无缝铁素体和奥氏体合金钢锅炉、过热器和换热器管标准规范

【概要描述】ASTM A213/A213M规范涵盖了无缝铁素体和奥氏体钢锅炉、过热器和换热器管。在其名称中包含字母H的等级的要求与不含字母H的类似等级的要求不同。这些不同的要求提供了比没有这些不同要求的类似等级通常可达到的更高的蠕变断裂强度。

- 分类:国外产品技术与服务

- 作者:www.negerekli.com中燃管道

- 来源:英国ladbrokes官方网站

- 发布时间:2024-09-24

- 访问量:82

ASTM A213/A213M Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes

ASTM A213/A213M无缝铁素体和奥氏体合金钢锅炉、过热器和换热器管标准规范

ASTM A213/A213M specification covers seamless ferritic and austenitic steel boiler, superheater, and heat-exchanger tubes. Grades containing the letter H in their designation have requirements different from those of similar grades not containing the letter H. These different requirements provide higher creep-rupture strength than normally achievable in similar grades without these different requirements. The tubes shall be made by the seamless process and shall be either hot finished or cold finished, as specified. Grade TP347HFG shall be cold finished. Heat treatment shall be done separately and in addition to heating for hot forming. The ferritic alloy and ferritic stainless steels shall be reheated. On the other hand, austenitic stainless steel tubes shall be furnished in the heat-treated condition. Alternatively, immediately after hot forming, while the temperature of the tubes is not less than the minimum solution temperature, tubes may be individually quenched in water or rapidly cooled by other means. Tension test, hardness test, flattening test, and flaring test shall be done to each tube. Also, each tube shall be subjected to the nondestructive electric test or hydrostatic test.

ASTM A213/A213M规范涵盖了无缝铁素体和奥氏体钢锅炉、过热器和换热器管。在其名称中包含字母H的等级的要求与不含字母H的类似等级的要求不同。这些不同的要求提供了比没有这些不同要求的类似等级通常可达到的更高的蠕变断裂强度。管子应采用无缝工艺制造,并应按规定进行热加工或冷加工。TP347HFG级应进行冷加工。除了热成型加热外,热处理应单独进行。铁素体合金和铁素体不锈钢应重新加热。另一方面,奥氏体不锈钢管应在热处理条件下提供。或者,在热成型后,当管的温度不低于最低溶液温度时,管可以单独在水中淬火或通过其他方式快速冷却。应对每根管子进行拉伸试验、硬度试验、压扁试验和扩口试验。此外,每根管子都应进行无损电试验或水压试验。

- Surface state表面状态

Austenitic steel pipe should be washed to remove the scale, when the use of bright annealing, you do not need pickling. 奥氏体钢管应清洗去除氧化皮,使用光亮退火时,不需要酸洗。 - Chemical analysis of finished products成品化学分析

It shall be analyzed from one billet or one pipe per furnace, and the chemical composition determined accordingly shall meet the specified requirements.

每炉应从一个钢坯或一根管子进行分析,相应确定的化学成分应符合规定的要求。

- Mechanical test and grain size机械试验和粒度

(1) Tensile test:Such as each batch of steel pipe ≤ 50 root, then take a sample for tensile test; each batch of steel pipe> 50, then two steel pipes should take two samples for tensile test.

- 拉伸试验:如每批钢管≤50根,则取样进行拉伸试验;每批钢管>50根,则两根钢管应取两个样品进行拉伸试验。

(2) Flattening test: in each batch of a finished tube at both ends of each sample to take a flattening test, but the root can not used as a flaring sample. - 压扁试验:在每批成品管的两端各取一个试样进行压扁试验,但根部不能用作扩口试样。

(3) Flaring test: in each batch of a finished tube at both ends of a sample for a flaring test, but the root canal can not be used as a flattening sample. - 扩口试验:在每批成品管两端各取一个样品进行扩口试验,但根管不能用作压扁样品。

(4) Hardness test: from each batch of two tubes on the sample to do Brinell or Rockwell hardness test. - 硬度测试:从每批两根管子上取样品做布氏或洛氏硬度测试。

(5) Water pressure test: each pipe should be hydrostatic test. When the buyer is specified, a non-destructive test may be used instead. - 水压试验:每根管道应进行水压试验。当指定买方时,可以使用无损检测代替。

(6) Grain size: according to ASME E112 standard test. 粒度:根据ASME E112标准测试。

ASTM A213/A213M -17 Standard Specification for Seamless Ferritic and Austenitic Alloy-Steel Boiler, Superheater, and Heat-Exchanger Tubes. This specification covers seamless ferritic and austenitic steel boiler, superheater, and heat-exchanger tubes. Grades containing the letter H in their designation have requirements different from those of similar grades not containing the letter H. These different requirements provide higher creep-rupture strength than normally achievable in similar grades without these different requirements. The tubes shall be made by the seamless process and shall be either hot finished or cold finished, as specified. Grade TP347HFG shall be cold finished. Heat treatment shall be done separately and in addition to heating for hot forming. The ferritic alloy and ferritic stainless steels shall be reheated. On the other hand, austenitic stainless steel tubes shall be furnished in the heat-treated condition. Alternatively, immediately after hot forming, while the temperature of the tubes is not less than the minimum solution temperature, tubes may be individually quenched in water or rapidly cooled by other means. Tension test, hardness test, flattening test, and flaring test shall be done to each tube. Also, each tube shall be subjected to the nondestructive electric test or hydrostatic test. This abstract is a brief summary of the referenced standard. It is informational only and not an official part of the standard; the full text of the standard itself must be referred to for its use and application. ASTM does not give any warranty express or implied or make any representation that the contents of this abstract are accurate, complete or up to date.

ASTM A213/A213M-17无缝铁素体和奥氏体合金钢锅炉、过热器和换热器管的标准规范。本规范涵盖了无缝铁素体和奥氏体钢锅炉、过热器和换热器管。在其名称中包含字母H的等级的要求与不含字母H的类似等级的要求不同。这些不同的要求提供了比没有这些不同要求的类似等级通常可达到的更高的蠕变断裂强度。管子应采用无缝工艺制造,并应按规定进行热加工或冷加工。TP347HFG级应进行冷加工。除了热成型加热外,热处理应单独进行。铁素体合金和铁素体不锈钢应重新加热。另一方面,奥氏体不锈钢管应在热处理条件下提供。或者,在热成型后,当管的温度不低于最低溶液温度时,管可以单独在水中淬火或通过其他方式快速冷却。应对每根管子进行拉伸试验、硬度试验、压扁试验和扩口试验。此外,每根管子都应进行无损电试验或水压试验。本摘要是对参考标准的简要总结。它仅供参考,不是标准的官方部分;使用和应用时必须参考标准本身的全文。ASTM不提供任何明示或暗示的保证,也不表示本摘要的内容是准确、完整或最新的。

Scope范围

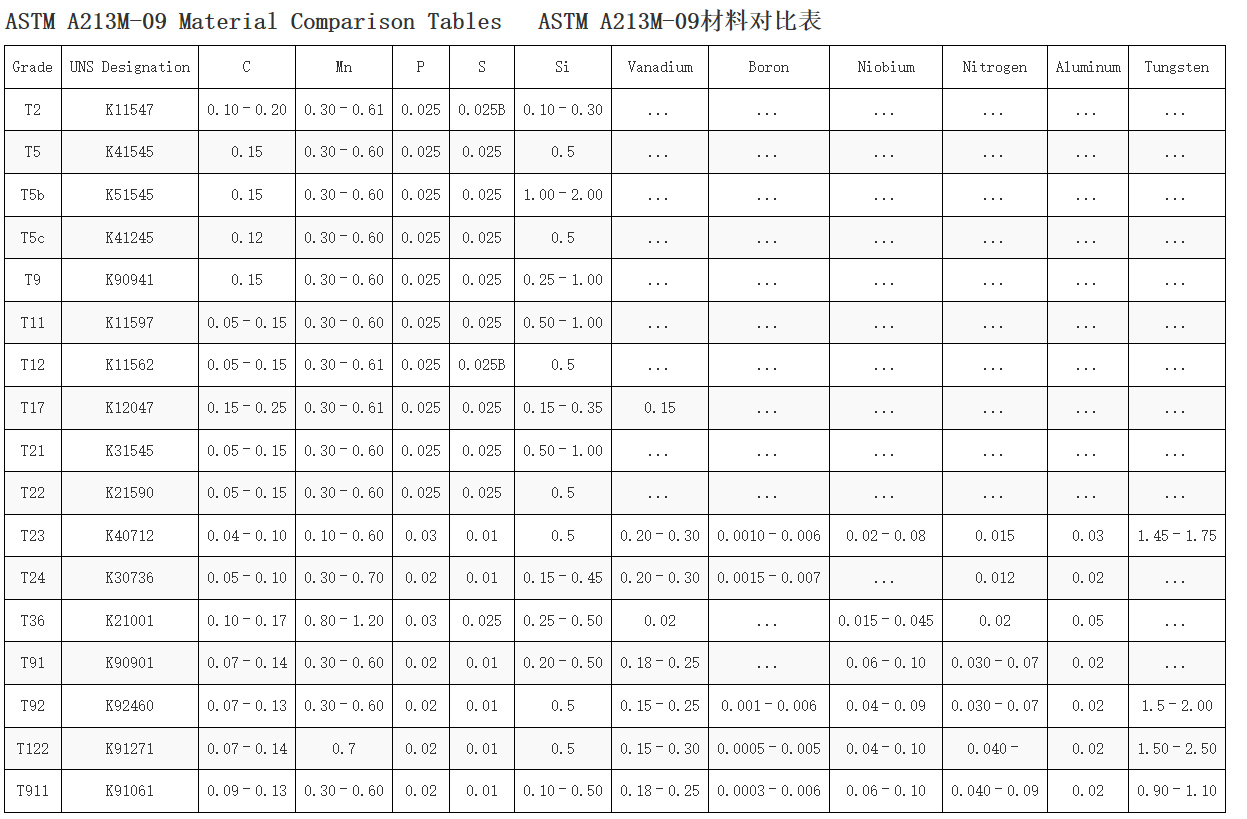

- Maximum, unless range or minimum is indicated. Where ellipses (...) appear in this table, there is no requirement, and analysis for the element need not be determined or reported.

- 最大值,除非指定了范围或最小值。如果此表中出现椭圆(…),则没有要求,也不需要确定或报告元素的分析。

(B) It is permissible to order T2 and T12 with a sulfur content of 0.045 max. See 16.3. - 允许订购硫含量最大为0.045的T2和T12。见16.3。

(C) Alternatively, in lieu of this ratio minimum, the material shall have a minimum hardness of 275 HV in the hardened condition, defined as after austenitizing and cooling to room temperature but prior to tempering. Hardness testing shall be performed at mid-thickness of the product. Hardness test frequency shall be two samples of product per heat treatment lot and the hardness testing results shall be reported on the material test report. - 或者,代替该最小比率,材料在硬化条件下的最小硬度应为275 HV,即奥氏体化和冷却至室温后但回火前。硬度测试应在产品的中间厚度进行。硬度测试频率应为每个热处理批次两个产品样品,硬度测试结果应在材料测试报告中报告。

(D) The terms Niobium (Nb) and Columbium (Cb) are alternate names for the same element. - 铌(Nb)和铌(Cb)是同一元素的替代名称。

(A) Maximum, unless a range or minimum is indicated. Where ellipses (...) appear in this table, there is no minimum and analysis for the element need not be determined or reported.

- 最大值,除非指定了范围或最小值。如果此表中出现椭圆(…),则没有最小值,也不需要确定或报告元素的分析。

(B) The method of analysis for Nitrogen shall be a matter of agreement between the purchaser and the producer. - 氮气的分析方法应由买方和生产商协商确定。

(C) For these alloys, there is no common grade designation. The UNS number uniquely identifies these alloys. - 对于这些合金,没有通用的牌号。UNS编号唯一标识这些合金。

(D) For small diameter or thin walls, or both, where many drawing passes are required, a carbon maximum of 0.040% is necessary in Grades TP304L, TP304LN, TP316L, and TP316LN. - 对于小直径或薄壁,或两者兼而有之,需要许多拉拔道次,TP304L、TP304LN、TP316L和TP316LN级的碳含量最高为0.040%。

(E) Grade S30434 shall have (Ti + 1/2 Nb) of not less than 2 times and not more than 4 times the carbon content. - S30434级应具有不小于2倍且不大于4倍的碳含量(Ti+1/2 Nb)。

(F) Grade TP347LN shall have an Nb content of not less than 15 times the carbon content. - TP347LN级的Nb含量不得低于碳含量的15倍

(G) Grade TP348 shall have an Nb + Ta content of not less than 10 times the carbon content and not more than 1.10%. - TP348级的Nb+Ta含量应不低于碳含量的10倍,且不超过1.10%。

(H) Grade TP348H shall have an Nb + Ta content of not less than 8 times the carbon content and not more than 1.10%. - TP348H级的Nb+Ta含量应不低于碳含量的8倍,且不超过1.10%。

(I) Iron shall be determined arithmetically by difference of 100 minus the sum of the other specified elements. - 铁应通过100减去其他指定元素之和的差值进行算术测定。

(J) Al + Ti shall be 0.85 % min; 1.20 % max. - Al+Ti应至少为0.85%;最大1.20%。

(K) Grade TP444 shall have Ni + Cu = 1.00 max. - TP444级应具有最大镍+铜=1.00。

(L) Grade TP444 shall have Ti + Nb content not less than 0.20 + 4(C+N) and not more than 0.80 %. - TP444级的Ti+Nb含量不得低于0.20+4(C+N),也不得超过0.80%。

(M) N08020 shall have an Nb + Ta content of not less than 8 times the carbon content and not more than 1.00%. - N08020的Nb+Ta含量不得低于碳含量的8倍,也不得超过1.00%。

(N) The terms Niobium (Nb) and Columbium (Cb) are alternate names for the same element. - 铌(Nb)和铌(Cb)是同一元素的替代名称。

Grades containing the letter, H, in their designation, have requirements different from those of similar grades not containing the letter, H. These different requirements provide higher creep-rupture strength than normally achievable in similar grades without these different requirements.

在其名称中包含字母H的等级的要求与不含字母H的类似等级的要求不同。这些不同的要求提供了比没有这些不同要求的类似等级通常可达到的更高的蠕变断裂强度。

The tubing sizes and thicknesses usually furnished to this specification are 1/8 in. [3.2 mm] in inside diameter to 5 in. [127 mm] in outside diameter and 0.015 to 0.500 in. [0.4 to 12.7 mm], inclusive, in minimum wall thickness or, if specified in the order, average wall thickness. Tubing having other diameters may be furnished, provided such tubes comply with all other requirements of this specification.

本规范中通常提供的管材尺寸和厚度为内径1/8英寸[3.2毫米]至外径5英寸[127毫米],最小壁厚为0.015至0.500英寸[0.4至12.7毫米],如果订单中有规定,则为平均壁厚。可以提供具有其他直径的管子,前提是这些管子符合本规范的所有其他要求。

The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard. The inch-pound units shall apply unless the “M” designation of this specification is specified in the order.

以国际单位制或英寸-磅单位表示的值应单独视为标准值。在文本中,国际单位制显示在括号中。每个系统中所述的值可能不是完全等效的;因此,每个系统都应独立使用。将两个系统的值结合起来可能会导致不符合标准。除非订单中指定了本规范的“M”名称,否则应采用英寸-磅单位。

Referenced Documents (purchase separately)参考文件(单独购买)

ASTM Standards ASTM标准

- A262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

- A262奥氏体不锈钢晶间腐蚀敏感性检测规程

- A941 Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys

- A941钢、不锈钢、相关合金和铁合金相关术语

- A1016/A1016M Specification for General Requirements for Ferritic Alloy Steel, Austenitic Alloy Steel, and Stainless Steel Tubes

- A1016/A1016M铁素体合金钢、奥氏体合金钢和不锈钢管的一般要求规范

- E112 Test Methods for Determining Average Grain Size

- E112测定平均粒径的试验方法

AWS Specifications AWS规范

- A5.23/A5.23M Specification for Low-Alloy Steel Electrodes and Fluxes for Submerged Arc Welding

- A5.23/A5.23M埋弧焊用低合金钢焊条和焊剂规范

- A5.5/A5.5M

- 5.5米/5.5米

Terminology术语

Definitionx—For definitions of terms used in this speci- fication, refer to Terminology A 941.

定义x——有关本规范中使用的术语的定义,请参阅术语A941。

Ordering Information订购信息

It shall be the responsibility of the purchaser to specify all requirements that are necessary for products under this specification. Such requirements to be considered include, but are not limited to, the following:买方应负责规定本规范下产品所需的所有要求。需要考虑的此类要求包括但不限于以下内容:

-

- Quantity (feet, metres, or number of lengths),

1.1数量(英尺、米或长度),

-

- Name of material (seamless tubes),

1.2材料名称(无缝管),

-

- Grade (Tables 1 and 2),

1.3等级(表1和表2),

-

- Condition (hot finished or cold finished),

1.4条件(热加工或冷加工),

-

- Controlled structural characteristics (see 6.3),

1.5受控结构特征(见6.3),

-

- Size (outside diameter and minimum wall thickness, unless average wall thickness is specified),

1.6尺寸(外径和最小壁厚,除非规定了平均壁厚),

-

- Length (specific or random),

1.7长度(特定或随机),

-

- Hydrostatic Test or Nondestructive Electric Test (see 10.1),

1.8水压试验或无损电试验(见10.1),

-

- Specification designation and year of issue,

1.9规范名称和发布年份,

-

- Increased sulfur (for machinability, see Note B, Table 1, and 15.3), and

1.10硫含量增加(可加工性见注B、表1和15.3),以及

-

- Special requirements and any supplementary require- ments selected.

1.11选择的特殊要求和任何补充要求。

General Requirements一般要求

Product furnished to this specification shall conform to the requirements of Specification A 1016/A 1016M, including any supplementary requirements that are indicated in the purchase order. Failure to comply with the general require- ments of Specification A 1016/A 1016M constitutes noncon- formance with this specification. In case of conflict between the requirements of this specification and Specification A 1016/ A 1016M, this specification shall prevail.

根据本规范提供的产品应符合规范A 1016/A 1016M的要求,包括采购订单中指出的任何补充要求。不符合规范A 1016/A 1016M的一般要求构成不符合本规范。如果本规范的要求与规范A 1016/A 1016M之间存在冲突,应以本规范为准。

Materials and Manufacture材料与制造

1 Manufacture and Condition—Tubes shall be made by the seamless process and shall be either hot finished or cold finished, as specified. Grade TP347HFG shall be cold finished.

1制造和条件——管子应采用无缝工艺制造,并应按规定进行热加工或冷加工。TP347HFG级应进行冷加工。

Heat Treatment热处理

1 Ferritic Alloy and Ferritic Stainlexx Steelx—The fer- ritic alloy and ferritic stainless steels shall be reheated for heat treatment in accordance with the requirements of Table 3. Heat treatment shall be carried out separately and in addition to heating for hot forming.

1铁素体合金和铁素体不锈钢应按照表3的要求重新加热进行热处理。热处理应单独进行,并在热成型加热之外进行。

2 Auxtenitic Stainlexx Steelx—All austenitic tubes shall be furnished in the heat-treated condition, and shall be heat treated in accordance with the requirements of Table 3. Alter- natively, immediately after hot forming, while the temperature of the tubes is not less than the minimum solution treatment temperature specified in Table 3, tubes may be individually quenched in water or rapidly cooled by other means (direct quenched).

2奥氏体不锈钢——所有奥氏体管应在热处理状态下提供,并应按照表3的要求进行热处理。或者,在热成型后,当管子的温度不低于表3中规定的最低固溶处理温度时,管子可以单独在水中淬火或通过其他方式快速冷却(直接淬火)。

3 If any controlled structural characteristics are required, these shall be so specified in the order as to be a guide as to the most suitable heat treatment.

3如果需要任何受控的结构特性,则应在订单中予以规定,作为最合适的热处理指南。

Heat Treatment and Grain Size RequirementsA热处理和粒度要求A

Note笔记

A Maximum, unless range or minimum is indicated. Where ellipses (...) appear in this table, there is no requirement, and analysis for the element need not be determined or reported.

A最大值,除非指定了范围或最小值。如果此表中出现椭圆(…),则没有要求,也不需要确定或报告元素的分析。

B It is permissible to order T2 and T12 with a sulfur content of 0.045 max. See 16.3.

B允许订购硫含量最大为0.045的T2和T12。见16.3。

C Alternatively, in lieu of this ratio minimum, the material shall have a minimum hardness of 275 HV in the hardened condition, defined as after austenitizing and cooling to room temperature but prior to tempering.

C或者,代替该最小比率,材料在硬化条件下的最小硬度应为275 HV,即奥氏体化和冷却至室温后但回火前的硬度。

Hardness test frequency shall be two samples of product per heat treatment lot and the hardness testing results shall be reported on the material test report.

硬度测试频率应为每个热处理批次两个产品样品,硬度测试结果应在材料测试报告中报告。

扫二维码用手机看

- 联系电话- 0317-6689999 6165555

- 业务邮箱- 9905791@qq.com

- 公司地址- 河北省沧州市盐山县千童大街沧州银行对面

- 联系电话- 0317-6689999 6165555

- 业务邮箱- 9905791@qq.com

- 公司地址- 河北省沧州市盐山县千童大街沧州银行对面

版权所有:英国ladbrokes官方网站 冀ICP备19004948号-6

热线:0317-6165555

热线:0317-6165555 9905791@qq.com

9905791@qq.com