GB3087是中国国家标准,规定了制造中低压锅炉用无缝钢管的技术要求

- 分类:国外产品技术与服务

- 作者:www.negerekli.com中燃管道

- 来源:英国ladbrokes官方网站

- 发布时间:2024-09-27

- 访问量:547

【概要描述】GB3087标准涵盖了各种等级的无缝碳钢管,包括10#、20#和其他低合金材料。这些管子用于建造锅炉、热交换器和压力容器,用于输送温度高达450°C、压力高达5.88 MPa的蒸汽、水和其他流体。

GB3087是中国国家标准,规定了制造中低压锅炉用无缝钢管的技术要求

【概要描述】GB3087标准涵盖了各种等级的无缝碳钢管,包括10#、20#和其他低合金材料。这些管子用于建造锅炉、热交换器和压力容器,用于输送温度高达450°C、压力高达5.88 MPa的蒸汽、水和其他流体。

- 分类:国外产品技术与服务

- 作者:www.negerekli.com中燃管道

- 来源:英国ladbrokes官方网站

- 发布时间:2024-09-27

- 访问量:547

GB3087 is a Chinese national standard that specifies the technical requirements for seamless steel tubes used in the manufacture of low and medium pressure boilers.

GB3087是中国国家标准,规定了制造中低压锅炉用无缝钢管的技术要求。

GB3087 standard covers a range of seamless carbon steel tubes with various grades, including 10#, 20#, and other low-alloy materials. The tubes are used in the construction of boilers, heat exchangers, and pressure vessels for conveying steam, water, and other fluids at temperatures up to 450°C, and pressures up to 5.88 MPa.

GB3087标准涵盖了各种等级的无缝碳钢管,包括10#、20#和其他低合金材料。这些管子用于建造锅炉、热交换器和压力容器,用于输送温度高达450°C、压力高达5.88 MPa的蒸汽、水和其他流体。

The GB3087 standard specifies the chemical composition, mechanical properties, and other technical requirements for the seamless steel tubes. For example, the standard requires that the tensile strength of the tubes should be no less than 410 MPa, and the yield strength should be no less than 245 MPa, as per [3]. In addition, the standard also sets out the testing methods and inspection requirements for ensuring the quality of the tubes.

GB3087标准规定了无缝钢管的化学成分、力学性能等技术要求。例如,标准要求管材的抗拉强度应不低于410 MPa,屈服强度应不小于245 MPa,如[3]所述。此外,该标准还规定了确保管材质量的测试方法和检验要求。

GB3087 is an important standard for the manufacturing of seamless steel tubes used in low and medium pressure boilers in China, ensuring that these tubes meet the necessary technical requirements and quality standards.

GB3087是我国中低压锅炉用无缝钢管制造的重要标准,确保这些钢管符合必要的技术要求和质量标准。

Scope范围

This standard specifies the dimensions, shape, weight, technical requirements, test methods, inspection rules, packaging, marking and quality specifications of seamless steel tubes for low and medium pressure boilers.

本标准规定了中低压锅炉用无缝钢管的尺寸、形状、重量、技术要求、试验方法、检验规则、包装、标志和质量规范。

This standard is applicable to the manufacture of high-quality carbon structural steel hot-rolled (extruded, expanded) and cold drawn (rolled) seamless steel tubes for various structural low-pressure and medium-pressure boilers and locomotive boilers.

本标准适用于各种结构低压、中压锅炉和机车锅炉用优质碳素结构钢热轧(挤压、膨胀)和冷拔(轧制)无缝钢管的制造。

Reference standard参考标准

The provisions contained in the following standards constitute provisions of this standard by reference in this standard. At the time of publication, the editions indicated were valid. All standards will be revised and parties using this standard should explore the possibility of using the latest version of the following standards.

下列标准中的规定通过在本标准中引用而构成本标准的规定。在出版时,所示版本是有效的。所有标准都将被修订,使用本标准的各方应探索使用以下标准最新版本的可能性。

- GB/T222—1984 Sample sampling method for chemical analysis of steel and chemical composition tolerance of finished products·

- GB/T222--1984钢材化学分析取样方法及成品化学成分允许偏差

- GB/T223.5-1997 Methods for chemical analysis of steels and alloys - Determination of acid-soluble silicon content by molybdate spectrophotometry·

- GB/T223.5-1997钢及合金化学分析方法钼酸盐分光光度法测定酸溶硅量

- GB/T 223.12—1991 Methods for chemical analysis of steels and alloys - Sodium carbonate - Diphenylcarbonyl hydrazide photometric method·

- GB/T 223.12--1991钢及合金化学分析方法碳酸钠二苯羰基酰肼光度法

- GB/T 223.19—1989 Chemical analysis methods for steel and alloys Xinyatongling-trichloromethane extraction·

- GB/T 223.19—1989钢铁及合金化学分析方法新牙岭三氯甲烷萃取法

- GB/T 223.23—1994 Methods for chemical analysis of steels and alloys - Determination of nickel content by succinimide spectrophotometry·

- GB/T 223.23--1994钢及合金化学分析方法丁二酰亚胺分光光度法测定镍量

- GB/T 223.62—1988 Methods for chemical analysis of steels and alloys - Determination of phosphorus content by butyl acetate extraction spectrophotometry·

- GB/T 223.62-1988钢及合金化学分析方法乙酸丁酯萃取分光光度法测定磷量

- GB/T 223.63—1988 Methods for chemical analysis of steels and alloys - Determination of manganese content by sodium periodate (potassium) photometric method·

- GB/T 223.63-1988钢及合金化学分析方法高碘酸钠(钾)光度法测定锰量

- GB/T 223.69—1997 Method for chemical analysis of steel and alloys. Determination of carbon content by gas volume method after combustion in tubular boilers·

- GB/T 223.69-1997钢及合金化学分析方法。管式锅炉燃烧后气体体积法测定碳含量

- GB/T 223.72—1991 Methods for chemical analysis of steels and alloys - Aluminium chromatographic separation - Barium sulfate gravimetric method·

- GB/T 223.72-1991钢及合金化学分析方法铝色谱分离硫酸钡重量法

- GB/T 226—1991 Low-fold structure of steel and defect acid etching test·

- GB/T 226--1991钢的低折组织和缺陷酸蚀试验

- GB/T 228—1987 Metal tensile test method·

- GB/T 228--1987金属拉伸试验方法

- GB/T 241—1990 Metal pipe hydraulic test method·

- GB/T 241--1990金属管水压试验方法

- GB/T 242—1997 Metal pipe flaring test method·

- GB/T 242--1997金属管扩口试验方法

- GB/T 244—1997 Metal tube bending test method·

- GB/T 244--1997金属管材弯曲试验方法

- GB/T 245—1997 Metal tube crimping test method·

- GB/T 245--1997金属管压接试验方法

- GB/T 246—1997 Metal tube flattening test method·

- GB/T 246--1997金属管压扁试验方法

- GB/T 699—1999 high quality carbon structural steel·

- GB/T 699--1999优质碳素结构钢

- GB/T 2102—1988 Acceptance, packaging, marking and quality instructions for steel pipes·

- GB/T 2102—1988钢管的验收、包装、标志和质量说明

- GB/T 5777-1996 Ultrasonic flaw detection test method for seamless steel tubes·

- GB/T 5777-1996无缝钢管超声波探伤试验方法

- GB/T 7735-1995 Steel pipe eddy current testing method·

- GB/T 7735-1995钢管涡流检测方法

- GB/T 12606—1999 Steel pipe leakage magnetic flaw detection method·

- GB/T 12606--1999钢管漏磁探伤方法

- GB/T 17395—1998 Seamless steel pipe size, shape, weight and tolerance·

- GB/T 17395--1998无缝钢管尺寸、形状、重量及允许偏差

- YB/T 5222-1993 high quality carbon round billet·

- YB/T 5222-1993优质碳素圆坯

size, shape, weight尺寸、形状、重量

1 Outer diameter and wall thickness

1外径和壁厚

-

- The outer diameter, wall thickness and theoretical weight of the steel pipe shall comply with the provisions of Table 1 of GB/T 17395-1998.

1.1钢管的外径、壁厚和理论重量应符合GB/T 17395-1998表1的规定。

Steel pipes of different specifications as specified in Table 1 of GB/T 17395-1998 may be supplied through negotiation between the supplier and the buyer.

GB/T 17395-1998表1中规定的不同规格的钢管可由供应商和买方协商提供。

-

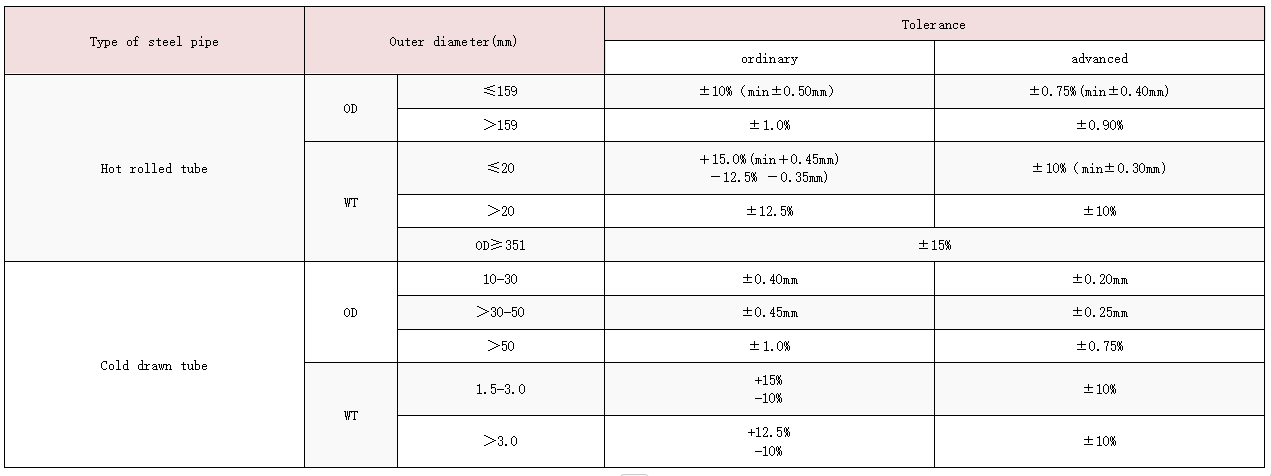

- The allowable deviation of the outer diameter and wall thickness shall comply with the requirements of Table 1.

1.2外径和壁厚的允许偏差应符合表1的要求。

When the purchaser requests to supply according to advanced precision, it should be indicated in the contract.

当买方要求按照先进精度供货时,应在合同中注明。

After consultation between the supplier and the buyer, and in the contract, it can produce steel pipes with deviations from those specified in Table 1.

供需双方协商,在合同中,可以生产与表1中规定的偏差的钢管。

GB 3087 Standard Seamless Boiler Alloy Steel Pipe Low Pressure Medium Pressure GB 3087标准无缝锅炉合金钢管低压中压

Table 1 Allowable deviation of outer diameter and wall thickness表1外径和壁厚的允许偏差

Chemical Composition(%) of GB 3087 GB 3087化学成分(%)

|

Standard |

Steel Grade |

C |

Si |

Mn |

S |

P |

Cr |

|

GB 3087 |

10 |

0.07-0.13 |

0.17-0.37 |

0.35-0.65 |

0.020 |

0.025 |

≤0.15 |

|

20 |

0.17-0.23 |

0.17-0.37 |

0.35-0.65 |

0.020 |

0.025 |

≤0.25 |

2 length长度

2.1 Normal length正常长度

The usual length of steel pipes is specified as follows:钢管的常用长度规定如下:

Hot-rolled (extruded, expanded) steel pipe............................................................4000~12000mm;

热轧(挤压、膨胀)钢管............................................................4000~12000mm;

Cold drawn (rolled) steel pipe.................................................................. 4000~10500mm.

冷拔(轧)钢管.................................................................. 4000~10500mm。

After consultation between the supplier and the buyer, the steel pipe with a length of not less than 3000mm can be delivered, but the weight must not exceed 5% of the total delivery weight of the batch of steel pipes.

经供需双方协商,长度不小于3000mm的钢管可以交付,但重量不得超过该批钢管总交付重量的5%。

2.2 Length and length of the ruler尺子的长度和长度

The length of the fixed length and the length of the double scale should be within the normal length range, and the full length tolerance is mm.

定尺长度和双尺长度应在正常长度范围内,全长公差为mm。

The length of each double ruler is set as follows:

每把双尺的长度设置如下:

OD ≤ 159mm..................................................................5~10mm;

2.3 Range length

The length of the range should be within the usual length range.

范围的长度应在通常的长度范围内。

3 Bending弯曲

The bending of the steel pipe shall not be greater than the following:

钢管的弯曲度不得超过以下数值:

Wall thickness ≤ 15mm..................................................................1.5mm/m;

Wall thickness >15mm..................................................................2.0mm/m;

Thermal expansion tube with an outer diameter of ≥ .................... 3.0mm/m.

4 tip shape尖端形状

The end faces of the steel pipe should be perpendicular to the axis of the steel pipe, and the burrs of the cut should be removed.

钢管的端面应垂直于钢管的轴线,并应去除切口的毛刺。

5 Unroundness and uneven wall thickness不圆度和壁厚不均匀

According to the requirements of the purchaser, the supplier and the buyer shall negotiate and indicate in the contract that the out-of-roundness and wall thickness of the same section of steel shall not exceed 80% of the outer diameter and wall thickness, respectively.

根据买方的要求,供应商和买方应协商并在合同中注明,同一截面钢的不圆度和壁厚不得分别超过外径和壁厚的80%。

6 Delivery weight交货重量

The delivery weight of steel pipes shall comply with the provisions of GB/T 19395. The density of the steel is calculated as 7.85 kg/dm3.

钢管的交货重量应符合GB/T 19395的规定。钢的密度计算为7.85kg/dm3。

7 Tag example标签示例

A steel pipe with an outer diameter of 76 mm and a wall thickness of 3.5 mm made of steel No. 10:

由10号钢制成的外径为76mm、壁厚为3.5mm的钢管:

- Hot-rolled steel pipe, the outer diameter and wall thickness are of ordinary grade accuracy, and the length is 3000mm.

a) 热轧钢管,外径和壁厚为普通级精度,长度为3000mm。

10-76×3.5×3000 times—GB 3087—1999

- Cold drawn (rolled) steel pipe, the outer diameter is advanced precision, the wall thickness is ordinary precision, and the length is 5000mm

b) 冷拔(轧)钢管,外径精度先进,壁厚精度一般,长度5000mm

Cold 10-76 high × 3.5 × 5000 times - GB 3087-1999

Technical requirements技术要求

1 Steel grades and chemical composition

1钢种和化学成分

Table 2 Chemical composition of steel pipes

表2钢管化学成分

Standard issuing unit: National Quality and Technical Supervision Bureau approved 1999-11-01

标准发布单位:国家质量技术监督局批准1999-11-01

Implementation date: 2000-08-01 implementation

实施日期:2000年8月1日实施

-

- The steel pipe is made of steel No. 10 and No. 20, and the chemical composition (melting analysis) shall comply with the provisions of GB/T 699. The steel pipe is inspected according to the olefinic components.

1.1钢管由10号和20号钢制成,化学成分(熔融分析)应符合GB/T 699的规定。钢管根据烯烃成分进行检验。

-

- When the requester requests the analysis of the finished product, it should be indicated in the contract.

1.2当请求者要求对成品进行分析时,应在合同中注明。

The chemical composition allowable deviation of the finished steel pipe shall comply with the provisions of GB/T222.

成品钢管的化学成分允许偏差应符合GB/T222的规定。

2 Manufacturing methods制造方法

2.1 Method of manufacturing steel2.1钢材制造方法

Steel shall be manufactured by electric furnace, oxygen converter or open hearth method. When the manufacturer specifies a certain manufacturing method, it shall be indicated in the contract; the steel directly used for continuous casting billet must be refined outside the furnace.

钢材应采用电炉、氧气转炉或平炉法制造。当制造商指定某种制造方法时,应在合同中注明;直接用于连铸坯的钢必须在炉外精炼。

2.2 Manufacturing method of tube blank管坯制造方法

The tube blank can be produced by a hot rolling method, and a continuous casting billet or a steel ingot can also be used. Hot rolled tube blanks shall comply with the provisions of YB/T 5222.

管坯可以通过热轧方法生产,也可以使用连铸坯或钢锭。热轧管坯应符合YB/T 5222的规定。

2.3 Manufacturing method of steel pipe钢管制造方法

The steel pipe can be manufactured by a hot rolling (extrusion, expansion) or cold drawing (rolling) seamless method. When the purchaser specifies a certain manufacturing method, it should be indicated in the contract.

钢管可以通过热轧(挤压、膨胀)或冷拔(轧制)无缝方法制造。当买方指定某种制造方法时,应在合同中注明。

3 Delivery status交货状态

Steel pipes shall be delivered in hot rolled or heat treated condition. The finishing temperature of the steel pipe delivered in the hot rolled state shall not be less than Ar3.

钢管应在热轧或热处理状态下交付。热轧状态下交付的钢管的终轧温度不得低于Ar3。

4 Mechanical properties机械性能

4.1 Delivery conditions The longitudinal mechanical properties of steel pipes are to comply with the requirements of Table 3.

4.1交货条件钢管的纵向力学性能应符合表3的要求。

Table 3 Longitudinal mechanical properties of steel tubes钢管纵向力学性能

|

Standard |

Steel pipe |

Wall thickness |

Tensile strength |

Yield Strength |

Elongation |

|

≥ |

|||||

|

GB3087 |

10 |

/ |

335-475 |

195 |

24 |

|

20 |

<15 |

410-550 |

245 |

20 |

|

|

≥15 |

225 |

||||

4.2 The high-temperature transient performance of the steel pipe used for medium-pressure boiler superheated steam pipe shall comply with the provisions of Table 4. The purchaser shall indicate the purpose of the steel pipe in the contract.

4.2中压锅炉过热蒸汽管道用钢管的高温瞬态性能应符合表4的规定。买方应在合同中注明钢管的用途。

According to the requirements of the purchaser, the supplier and the buyer shall negotiate and indicate the test temperature in the contract, and the supplier shall provide the actual high-temperature transient performance data of the steel pipe.

根据买方的要求,供应商和买方应协商并在合同中注明试验温度,供应商应提供钢管的实际高温瞬态性能数据。

Table 4 Minimum yield strength of steel pipe at high temperature高温下钢管的最小屈服强度

|

Steel grade |

Sample status |

Temperature,℃ |

|||||

|

200 |

250 |

300 |

350 |

400 |

450 |

||

|

10 |

Delivery status |

165 |

145 |

122 |

111 |

109 |

107 |

|

20 |

188 |

170 |

149 |

137 |

134 |

132 |

|

5 Process test工艺试验

5.1 Hydraulic test水压试验

The steel pipe should be hydraulically tested one by one.钢管应逐一进行水压试验。

The supplier can replace the hydraulic test with eddy current testing. Ultrasonic testing or magnetic flux leakage testing can also be used instead of hydraulic testing after consultation between the supplier and the buyer. When using eddy current flaw detection, the grade A hole of GB/T 7735-1994 should be used; when ultrasonic flaw detection, the depth grade of the longitudinal notch groove on the outer surface of the comparison sample tube should meet the requirements of C8 in GB/T5777-1996; The longitudinal notch groove on the outer surface of the comparative sample tube shall comply with the provisions of N12.5 in GB/T 12606-1999, with a minimum depth of 0.5 mm and a maximum depth of 1.5 mm.

供应商可以用涡流检测代替液压测试。经供需双方协商后,也可以使用超声波检测或漏磁检测代替液压检测。使用涡流探伤时,应使用GB/T 7735-1994的A级孔;超声波探伤时,对比样品管外表面纵向切口槽的深度等级应符合GB/T577-1996中C8的要求;对比样品管外表面上的纵向凹槽应符合GB/T 12606-1999中N12.5的规定,最小深度为0.5mm,最大深度为1.5mm。

5.2 Flattening test压扁试验

Steel pipes with an outer diameter of more than 22mm to 400mm and a wall thickness of not more than 10mm shall be subjected to a flattening test.

外径大于22mm至400mm、壁厚不超过10mm的钢管应进行压扁试验。

No cracks or cracks shall appear on the specimen after the flattening test.

压扁试验后,试样上不得出现裂纹。

5.3 crimping test压接试验

According to the requirements of the purchaser, the supply and demand sides negotiate and indicate in the contract that the steel pipe made of No. 10 steel can be subjected to the crimping test.根据买方的要求,供需双方协商并在合同中明确表示,10号钢制成的钢管可以进行压接试验。

The curling width (measured by the inner wall) shall not be less than 12% of the nominal inner diameter, nor less than 1.5 times the nominal wall thickness, and the curling angle shall be 90°. No cracks or cracks shall occur outside the sample curl after crimping.

卷曲宽度(由内壁测量)不得小于标称内径的12%,也不得小于标称壁厚的1.5倍,卷曲角度应为90°。压接后,样品卷曲外不得出现裂纹或裂纹。

5.4 Flaring test扩口试验

According to the requirements of the purchaser, the supply and demand sides negotiate and indicate in the contract that the steel pipe with a wall thickness of not more than 8 mm can be subjected to a flare test with a top taper of 30°, 45° or 60°. No cracks or cracks shall appear on the specimen after flaring.

根据买方的要求,供需双方协商并在合同中明确表示,壁厚不超过8mm的钢管可以进行顶部锥度为30°、45°或60°的扩口试验。扩口后试样上不得出现裂纹。

The flaring ratio of the outer diameter of the sample after flaring shall comply with the requirements of Table 5.

扩口后样品外径的扩口比应符合表5的要求。

Table 5 steel pipe outer diameter expansion rate钢管外径膨胀率

|

Standard |

Steel grade |

steel pipe outer diameter expansion rate,% |

||

|

Inside diameter / outer diameter |

||||

|

≤0.6 |

>0.6-0.8 |

>0.8 |

||

|

GB3087 |

10 |

12 |

15 |

19 |

|

20 |

10 |

12 |

17 |

|

5.5 Bending test弯曲试验

Steel pipes with an outer diameter of not more than 22 mm shall be subjected to a bending test with a bending angle of 90° and a radius of curvature of six times the outer diameter of the steel pipe. There must be no cracks or cracks in the bend.

外径不超过22mm的钢管应进行弯曲试验,弯曲角度为90°,曲率半径为钢管外径的六倍。弯曲处不得有裂缝或裂纹。

According to the requirements of the purchaser, the supply and demand sides negotiate and indicate in the contract that the steel pipe for the locomotive boiler can be bent. The bending angle and the radius of the core are negotiated by both the supplier and the buyer.

根据买方的要求,供需双方协商并在合同中明确表示,机车锅炉的钢管可以弯曲。弯曲角度和芯半径由供应商和买方协商确定。

6 Low-power test低功率试验

For steel pipes directly manufactured by continuous casting billet or steel ingot, the supplier shall ensure that there are no white spots, inclusions, slag inclusions, skin turning, delamination and subcutaneous air bubbles on the cross-section acid-leaching low-strength test piece of the steel pipe or the blank.

对于直接由连铸坯或钢锭制造的钢管,供应商应确保钢管或毛坯的横截面酸浸低强度试件上没有白点、夹杂物、夹渣、表面车削、分层和皮下气泡。

7 Surface quality表面质量

The inner and outer surfaces of the steel pipe are not allowed to have cracks, folds, creases, crusting or separation, and these defects should be completely removed. The clearance depth shall not exceed the negative deviation of the nominal wall thickness, and the actual wall thickness at the cleaning site shall not be less than the minimum allowed by the wall.

钢管的内外表面不得有裂纹、褶皱、折痕、结痂或分离,这些缺陷应完全清除。间隙深度不得超过公称壁厚的负偏差,清洗现场的实际壁厚不得小于壁厚允许的最小值。

Straight road allowed depth:直道允许深度:

Cold drawn (rolled) steel pipe: not more than 4% of the wall thickness, the maximum depth is 0.3mm;

冷拔(轧)钢管:不超过壁厚的4%,最大深度为0.3mm;

Hot-rolled (extruded, expanded) steel pipe: not more than 5% of the wall thickness, the maximum depth is 0.5mm.

热轧(挤压、膨胀)钢管:不超过壁厚的5%,最大深度为0.5mm。

Other defects where the depth does not exceed the wall thickness negative deviation and the remaining wall thickness is not less than the minimum allowed by the wall thickness are allowed to exist.允许存在深度不超过壁厚负偏差且剩余壁厚不小于壁厚允许的最小值的其他缺陷。

4.8 Non-destructive testing无损检测

According to the requirements of the purchaser, after consultation between the supplier and the buyer, and in the contract, the steel pipe can be ultrasonically tested one by one. The depth of the longitudinal notch groove on the outer surface of the sample pipe should meet the requirements of C8 in GB/T 5777-1996.

根据买方的要求,经供需双方协商,并在合同中,钢管可以逐一进行超声波检测。样品管外表面纵向凹槽的深度应符合GB/T 5777-1996中C8的要求。

Test methods试验方法

1 The size of the steel pipe shall be measured one by one using gauges that meet the accuracy requirements.

1钢管的尺寸应使用符合精度要求的量规逐一测量。

2 The inner and outer surfaces of steel pipes shall be visually inspected one by one.

2钢管内外表面应逐一进行目视检查。

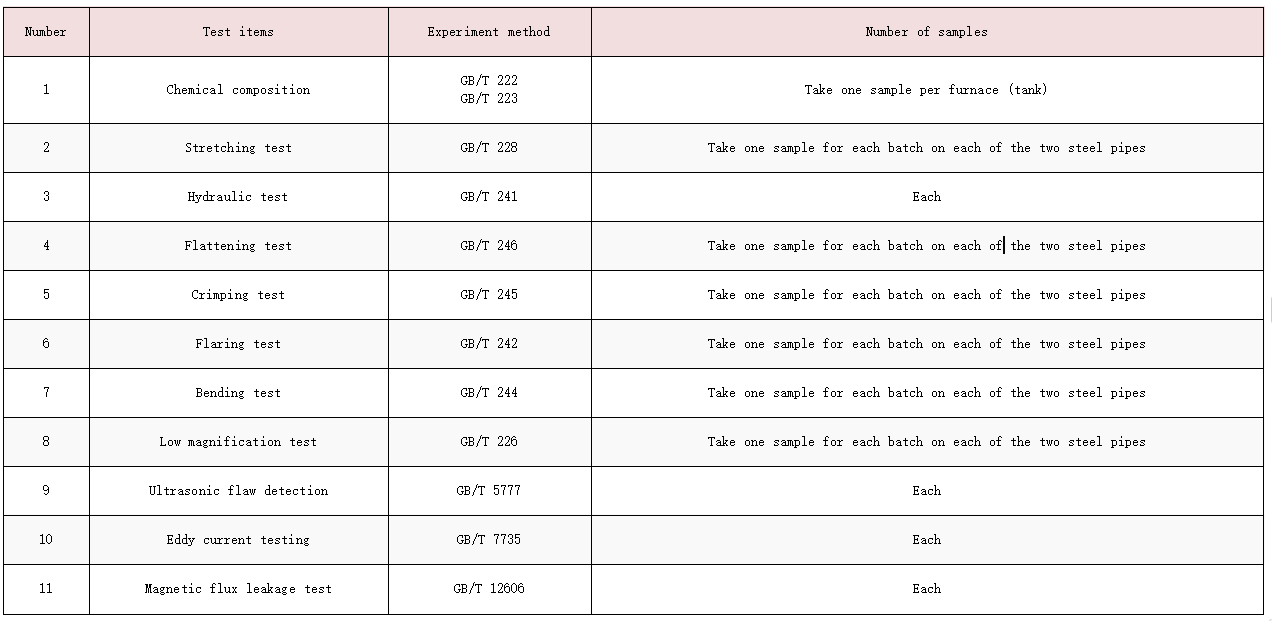

3 Other inspection items for steel pipes shall comply with the requirements of Table 6.

3钢管的其他检验项目应符合表6的要求。

Table 6 Inspection items, sampling quantities and test methods for steel pipes钢管检验项目、取样数量及试验方法

Inspection rules检验规则

1 Inspection and acceptance检查验收

The inspection and acceptance of steel pipes shall comply with the provisions of GB/T 2102.钢管的检验和验收应符合GB/T 2102的规定。

2 Batch rule批处理规则

The steel pipes are inspected and accepted in batches. Each batch shall consist of steel pipes of the same grade, the same furnace (tank) number, the same specification and the same heat treatment system (heating).

钢管分批验收。每批应由相同等级、相同炉(罐)号、相同规格和相同热处理系统(加热)的钢管组成。

All pipe sections taken from double-length long seamless steel pipes shall be considered as one.

所有取自双倍长度长无缝钢管的管段应视为一个。

The number of roots of each batch of steel pipes does not exceed the following:

每批钢管的根数不超过以下值:

The outer diameter is not more than 76mm, and the wall thickness is not more than 3mm......................................................400 PCS;

外径不大于76mm,壁厚不大于3mm......................................................400件;

Outer diameter is greater than 351mm....................................................................................50 PCS;

外径大于351mm....................................................................................50件;

Other sizes of steel pipes..........................................................................................200 PCS.

其他尺寸的钢管..........................................................................................200件。

When the number of remaining steel pipes is not less than 50% as specified above, it shall be listed as a batch; if it is less than 50% of the above, it may be incorporated into the same grade, the same furnace (can) number, the same specification and the same heat treatment system (furnace) Next) in the adjacent batch.

当剩余钢管数量不少于上述规定的50%时,应按批次列出;如果低于上述50%,则可以将其合并到相邻批次中的相同等级、相同炉(罐)号、相同规格和相同热处理系统(炉)Next)中。

3 Number of samples样本数量

The sampling quantity of each inspection item of each batch of steel pipe shall be as specified in Table 6.

每批钢管的每个检验项目的取样数量应符合表6的规定。

4 Re-inspection and decision rules复检和决策规则

The re-inspection and determination rules of steel pipes shall comply with the provisions of GB/T 2102.

钢管复验判定规则应符合GB/T 2102的规定。

Packaging, marking and quality instructions包装、标记和质量说明

The packaging, marking and quality specifications of steel pipes shall comply with the provisions of GB/T 2102.

钢管的包装、标志和质量规格应符合GB/T 2102的规定。

Test Requirement测试要求

Flattening Test压扁试验

Steel Tubes With An Outer Diameter Greater Than 22 Mm And Up To 400 Mm, And Wall Thickness Greater Than 10 Mm Should Undergo The Flattening Test. After The Samples Are Flattened

外径大于22mm至400mm、壁厚大于10mm的钢管应进行压扁试验。样品压平后

Bending Test弯曲试验

Steel Tubes With An Outer Diameter Not Greater Than 22 Mm Should Undergo The Bending Test. The Bending Angle Is 90o . The Bending Radius Is 6 Times The Outer Diameter Of The Steel Tube.After Bending The Sample, No Fissures Or Cracks Are Permitted To Appear On The Sample.

外径不大于22Mm的钢管应进行弯曲试验。弯曲角度为90度。弯曲半径是钢管外径的6倍。弯曲样品后,样品上不允许出现裂缝或裂纹。

Macroscopic Examination宏观检查

For Steel Tubes Directly Made By Continuously Cast Billets Or Steel Ingots, The Supplying Party Should Guarantee That There Are No White Spots, Impurities, Sub-Surface Air Bubbles, Skull Patches Or Layering On The Cross-Sectional Acid Pickled Macroscopic Tissue Of The Billet Or Steel Tube.

对于直接由连铸钢坯或钢锭制成的钢管,供应方应保证钢坯或钢管的酸洗宏观组织横截面上没有白点、杂质、亚表面气泡、颅骨斑或分层。

Non-Destructive Inspection无损检测

According To The Demanding Party’s Request, Which Is Then Negotiated Between The Supplying And Demanding Parties And Indicated In The Agreement, Ultrasonic Flaw Detection May Be Individually Performed For Steel Tubes. The Longitudinal Manual Defect Of The Reference Sample Tube Should Meet The Requirements For Post-Inspection Acceptance Grade C8 Specified In GB/T 5777-1996.

根据需求方的要求,然后供需双方协商并在协议中指出,钢管可以单独进行超声波探伤。参考样品管的纵向手动缺陷应符合GB/T 5777-1996规定的C8级检验后验收要求。

Related GB3087相关GB3087

扫二维码用手机看

- 联系电话- 0317-6689999 6165555

- 业务邮箱- 9905791@qq.com

- 公司地址- 河北省沧州市盐山县千童大街沧州银行对面

- 联系电话- 0317-6689999 6165555

- 业务邮箱- 9905791@qq.com

- 公司地址- 河北省沧州市盐山县千童大街沧州银行对面

版权所有:英国ladbrokes官方网站 冀ICP备19004948号-6

热线:0317-6165555

热线:0317-6165555 9905791@qq.com

9905791@qq.com