ASTM A335/A335M高温用无缝铁素体合金钢管标准规范

- 分类:国外产品技术与服务

- 作者:www.negerekli.com中燃管道

- 来源:英国ladbrokes官方网站

- 发布时间:2024-09-24

- 访问量:582

【概要描述】本规范涵盖高温用无缝铁素体合金钢管。管道应适用于弯曲、翻边(vanstoning)和类似的成型操作,以及熔焊。P2和P12级钢管应采用粗晶粒熔炼工艺制造。钢材应符合化学成分、拉伸性能和硬度要求。

ASTM A335/A335M高温用无缝铁素体合金钢管标准规范

【概要描述】本规范涵盖高温用无缝铁素体合金钢管。管道应适用于弯曲、翻边(vanstoning)和类似的成型操作,以及熔焊。P2和P12级钢管应采用粗晶粒熔炼工艺制造。钢材应符合化学成分、拉伸性能和硬度要求。

- 分类:国外产品技术与服务

- 作者:www.negerekli.com中燃管道

- 来源:英国ladbrokes官方网站

- 发布时间:2024-09-24

- 访问量:582

ASTM A335/A335M Standard Specification for Seamless Ferritic Alloy-Steel Pipe for High-Temperature Service.

ASTM A335/A335M高温用无缝铁素体合金钢管标准规范。

This specification covers seamless ferritic alloy-steel pipe for high-temperature service. The pipe shall be suitable for bending, flanging (vanstoning), and similar forming operations, and for fusion welding. Grade P2 and P12 steel pipes shall be made by coarse-grain melting practice. The steel material shall conform to chemical composition, tensile property, and hardness requirements. Each length of pipe shall be subjected to the hydrostatic test. Also, each pipe shall be examined by a non-destructive examination method in accordance to the required practices. The range of pipe sizes that may be examined by each method shall be subjected to the limitations in the scope of the respective practices. The different mechanical test requirements for pipes, namely, transverse or longitudinal tension test, flattening test, and hardness or bend test are presented.

本规范涵盖高温用无缝铁素体合金钢管。管道应适用于弯曲、翻边(vanstoning)和类似的成型操作,以及熔焊。P2和P12级钢管应采用粗晶粒熔炼工艺制造。钢材应符合化学成分、拉伸性能和硬度要求。每段管道都应进行静水压试验。此外,应按照要求的做法,采用无损检测方法对每根管道进行检查。每种方法可以检查的管道尺寸范围应受到各自实践范围的限制。介绍了管道的不同力学试验要求,即横向或纵向拉伸试验、压扁试验和硬度或弯曲试验。

What is ASTM A335 material? ASTM A335材料是什么?

ASTM A335 is a standard specification for seamless ferritic alloy-steel pipe intended for high-temperature service. This material is commonly used in power plants, refineries, and other industrial settings where high-temperature and high-pressure conditions are encountered. The "A" in ASTM A335 stands for "alloy," indicating that the pipe is made from alloy steel, which typically includes elements such as chromium, molybdenum, and sometimes vanadium to enhance its high-temperature properties.

ASTM A335是用于高温环境的无缝铁素体合金钢管的标准规范。这种材料通常用于发电厂、炼油厂和其他遇到高温高压条件的工业环境。ASTM A335中的“A”代表“合金”,表示管道由合金钢制成,通常包括铬、钼等元素,有时还包括钒,以提高其高温性能。

Scope范围

1 This specification covers nominal wall and minimum wall seamless ferritic alloy-steel pipe intended for high-temperature service. Pipe ordered to this specification shall be suitable for bending, flanging (vanstoning), and similar forming operations, and for fusion welding. Selection will depend upon design, service conditions, mechanical properties, and high-temperature characteristics.

1本规范涵盖了用于高温环境的标称壁厚和最小壁厚无缝铁素体合金钢管。根据本规范订购的管道应适用于弯曲、翻边(vanstoning)和类似的成型操作,以及熔焊。选择将取决于设计、使用条件、机械性能和高温特性。

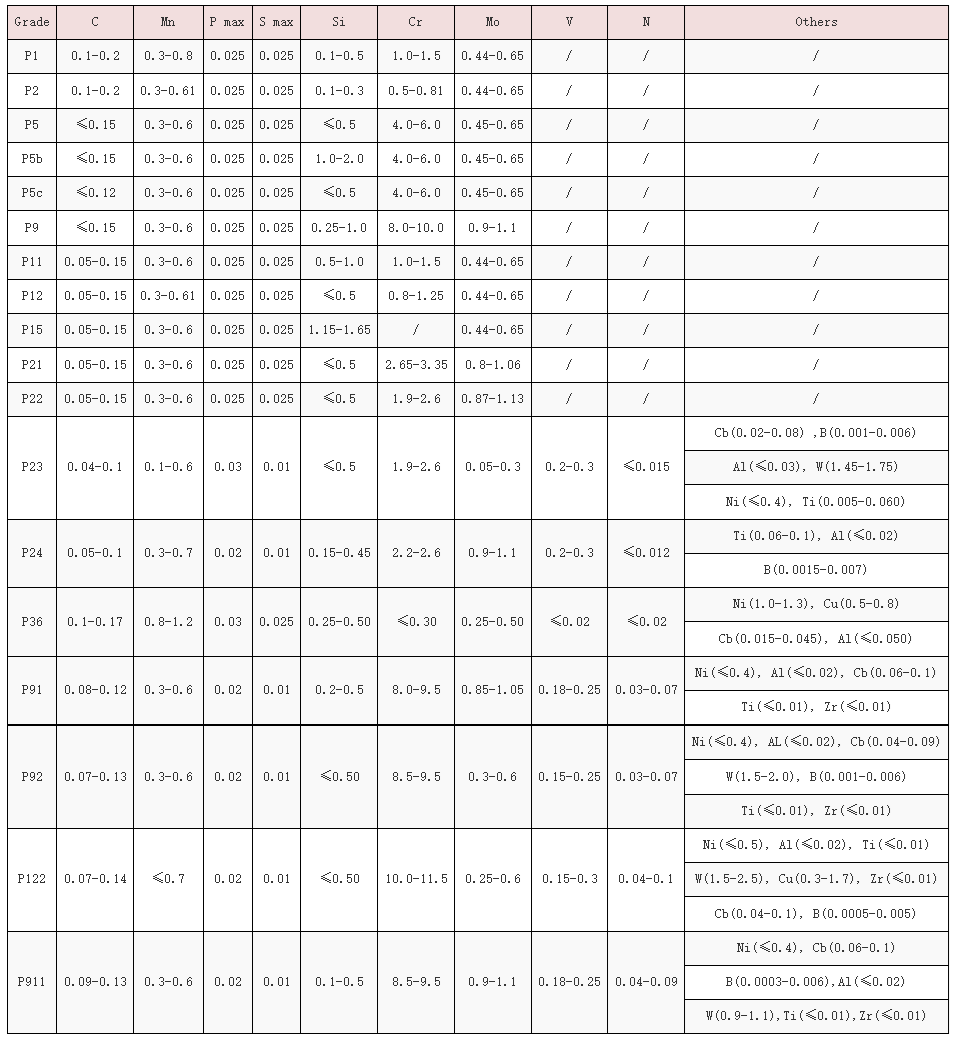

2 Several grades of ferritic steels (see Note 1) are covered. Their compositions are given in Table 1.

2涵盖了几种等级的铁素体钢(见注释1)。它们的组成如表1所示。

Note 1.. Ferritic steels in this specification are defined as low- and intermediate-alloy steels containing up to and including 10% chromium.

注1.本规范中的铁素体钢是指铬含量高达10%的低合金钢和中合金钢。

3 Supplementary requirements (S1 to S7) of an optional nature are provided. These supplementary requirements call for additional tests to be made, and when desired, shall be so stated in the order together with the number of such tests required.

3提供了可选性质的补充要求(S1至S7)。这些补充要求要求进行额外的测试,如有需要,应在订单中注明所需的测试次数。

4 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. The inch-pound units shall apply unless the "M" designation of this specification is specified in the order.

4以英寸-磅单位或国际单位表示的值应单独视为标准值。在文本中,国际单位制显示在括号中。每个系统中所述的值不是完全等效的;因此,每个系统都必须独立使用。结合两个系统的值可能会导致不符合规范。除非订单中指定了本规范的“M”名称,否则应采用英寸-磅单位。

Note The dimensionless designator NPS (nominal pipe size) has been substituted in this standard for such traditional terms as "nominal diameter", "size", and "nominal size".

注:本标准中用无量纲指示符NPS(公称管道尺寸)代替了“公称直径”、“尺寸”和“公称尺寸”等传统术语。

Why ASTM A335 seamless steel pipe is popular in high temperature application? 为什么ASTM A335无缝钢管在高温应用中很受欢迎?

ASTM A335 Seamless Steel Pipe is generally named chrome moly pipe for the chemical elements- Molybdenum and Chromium. Molybdenum improves steel performances as steel strength, elastic limit, wear resistance, impact and hardenability.

ASTM A335无缝钢管因其化学元素——钼和铬,通常被称为铬钼管。钼提高了钢的强度、弹性极限、耐磨性、冲击性和淬透性等性能。

ASTM A335 seamless steel pipe is a popular choice for high-temperature applications due to several key reasons:

ASTM A335无缝钢管是高温应用的热门选择,原因有几个:

- High-temperature resistance: ASTM A335 seamless steel pipe is designed to withstand high temperatures up to 600°C (1112°F), making it an ideal material for high-temperature applications such as steam pipelines and heat exchangers.

1.耐高温:ASTM A335无缝钢管的设计可承受高达600°C(1112°F)的高温,使其成为蒸汽管道和换热器等高温应用的理想材料。

- Corrosion resistance: ASTM A335 seamless steel pipe exhibits good corrosion resistance in aggressive environments, such as those found in chemical processing and oil and gas industries.

2.耐腐蚀性:ASTM A335无缝钢管在化学加工和石油天然气工业等侵蚀性环境中具有良好的耐腐蚀性。

- High strength: ASTM A335 seamless steel pipe has high tensile strength and yield strength, making it ideal for use in high-pressure applications.

3.高强度:ASTM A335无缝钢管具有高抗拉强度和屈服强度,是高压应用的理想选择。

- Good weldability: ASTM A335 seamless steel pipe can be easily welded using traditional methods, with no need for preheating or post-weld heat treatment.

4.良好的焊接性:ASTM A335无缝钢管可以使用传统方法轻松焊接,无需预热或焊后热处理。

- Uniform properties: ASTM A335 seamless steel pipe is produced using a consistent manufacturing process, ensuring that each pipe has uniform properties and quality.

5.性能均匀:ASTM A335无缝钢管采用一致的制造工艺生产,确保每根管道具有均匀的性能和质量。

- Cost-effective: Despite its superior properties, ASTM A335 seamless steel pipe remains an affordable option for high-temperature applications.

6.成本效益:尽管ASTM A335无缝钢管具有优越的性能,但对于高温应用来说,它仍然是一种经济实惠的选择。

In summary, ASTM A335 seamless steel pipe is popular in high-temperature applications due to its high-temperature resistance, corrosion resistance, high strength, good weldability, uniform properties, and cost-effectiveness. Its combination of properties makes it an ideal choice for use in various high-temperature and high-pressure applications, especially in the power generation, chemical processing, and oil and gas industries.

综上所述,ASTM A335无缝钢管因其耐高温、耐腐蚀、强度高、可焊性好、性能均匀、成本效益高等优点,在高温应用中广受欢迎。其综合性能使其成为各种高温高压应用的理想选择,特别是在发电、化学加工和石油天然气行业。

Referenced Documents (purchase separately) 参考文件(单独购买)

- A999/A999M Specification for General Requirements for Alloy and Stainless Steel Pipe

- A999/A999M合金和不锈钢管一般要求规范

- E213 Practice for Ultrasonic Examination of Metal Pipe and Tubing

- E213金属管道超声波检验规程

- E309 Practice for Eddy-Current Examination of Steel Tubular Products Using Magnetic Saturation

- E309使用磁饱和法对钢管产品进行涡流检测的实施规程

- E381 Method of Macroetch Testing Steel Bars, Billets, Blooms, and Forgings

- E381钢筋、钢坯、钢坯和锻件宏观腐蚀试验方法

- E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

- E527统一编号系统(UNS)中金属和合金编号的实施规程

- E570 Practice for Flux Leakage Examination of Ferromagnetic Steel Tubular Products

- E570铁磁性钢管产品漏磁检验规程

- B36.10M Welded and Seamless Wrought Steel Pipe

- B36.10M焊接和无缝锻钢管

- SAE J 1086 Practice for Numbering Metals and Alloys (UNS)

- SAE J 1086金属和合金编号规程(UNS)

- SNT-TC-1A Recommended Practice for Nondestructive Personnel Qualification and Certification、

- SNT-TC-1A无损人员资格鉴定和认证推荐规程

Chemical Composition(%) of ASTM A335 pipe ASTM A335管道的化学成分(%)

ASTM Specification pipe confirming to ASTM A335 shall have the following chemical properties. Tensile and Hardness Requirements The tensile properties of the ASTM A335 pipe shall conform to the requirements as prescribed. Pipe of Grades P91, P92, and P122 shall have a hardness not exceeding 250 HB/265 HV [25 HRC]. For pipe of Grades P91, P92, P122, and P911, Brinell, Vickers, or Rockwell hardness tests shall be made on a specimen from each lot (see Note 7). These pipe bear high resistance to rupture at high temperature and pressures. With hydrogen crack resistance and sulfide stress corrosion cracking chrome moly pipe are highly preferred over Carbon pipe.

符合ASTM A335的ASTM规范管道应具有以下化学性能。拉伸和硬度要求ASTM A335管道的拉伸性能应符合规定的要求。P91、P92和P122级管道的硬度不得超过250 HB/265 HV[25 HRC]。对于P91、P92、P122和P911级的管道,应对每批试样进行布氏、维氏或洛氏硬度试验(见注释7)。这些管道在高温高压下具有很高的抗破裂性。铬钼管具有抗氢裂纹和硫化物应力腐蚀开裂性能,比碳管更受欢迎。

Chrome Moly Pipes: Werkstoff vs EN vs ASTM 铬钼管:Werkstoff与EN与ASTM

ASTM A335 pipe may be either hot finished or cold drawn with the finishing treatment as required in Grade P2 and P12 – The steel shall be made by coarse- grain melting practice. Specific limits, if any, on grain size or deoxidation practice shall be a matter of agreement between the manufacturer and purchaser.

ASTM A335管道可进行热精加工或冷拔,并按照P2和P12级的要求进行精加工处理。钢材应采用粗晶粒熔炼工艺制造。粒径或脱氧实践的具体限制(如有)应由制造商和买方协商确定。

|

Werkstoff /DIN |

EN |

ASTM |

|

1.5415 |

16Mo3 |

A335 Grade P1 |

|

1.7335 |

13CrMo4-5 |

A335 Grade P11, P12 |

|

1.738 |

10CrMo9-10 |

A335 Grade P22 |

|

1.7362 |

X11CrMo5 |

A335 Grade P5 |

|

|

|

A335 Grade P9 |

|

1.4903 |

X10CrMoVNb9-1 |

A335 Grade P91 |

Tensile Requirements拉伸要求

|

Tensile Strength, min., psi |

P-5 |

P-9 |

P-11 |

P-22 |

P-91 |

|

ksi |

60 |

60 |

60 |

60 |

85 |

|

MPa |

415 |

415 |

415 |

415 |

585 |

|

Yield Strength, min., psi |

|

|

|

|

|

|

ksi |

30 |

30 |

30 |

30 |

60 |

|

MPa |

205 |

205 |

205 |

205 |

415 |

Product Analysis At the request of the purchaser, an analysis of two pipe from each lot shall be made by the manufacturer. A lot of ASTM A335 pipe shall consist of the following: NPS Designator Under 2 400 or fraction thereof 2 to 5 200 or fraction thereof 6 and over 100 or fraction thereof. Note: ASTM A335 P91 shall not have a hardness not exceeding 250 HB/265 HV [25HRC].

产品分析应买方要求,制造商应对每批中的两根管道进行分析。许多ASTM A335管道应由以下部分组成:NPS指示符2 400以下或2至5 200以下或6至100以上或其部分。注:ASTM A335 P91的硬度不得超过250 HB/265 HV[25HRC]。

Mechanical properties of ASTM A335 ASTM A335的机械性能

|

Grade |

Tensile strength |

Yield strength |

|

P1,P2 |

380 |

205 |

|

P12 |

415 |

220 |

|

P23 |

510 |

400 |

|

P91 |

585 |

415 |

|

P92,P11 |

620 |

440 |

|

P122 |

620 |

400 |

It also enhances the corrosion resistance of steel, and inhibits pitting. Chromium (or chrome) is the essential constituent of stainless steel. Any steel with 12% or more Chrome is considered stainless. Chrome is virtually irreplaceable in resisting oxidation at elevated temperatures. Chrome raises the tensile, yield, and hardness at room temperatures. The composition chrome moly alloy steel pipe make it ideal for use in power plants, refineries, petro chemical plants, and oil field services where fluids and gases are transported at extremely high temperatures and pressures.

它还增强了钢的耐腐蚀性,并抑制了点蚀。铬(或铬)是不锈钢的基本成分。任何含有12%或更多铬的钢都被认为是不锈钢。铬在高温下抗氧化方面几乎是不可替代的。铬在室温下提高了拉伸强度、屈服强度和硬度。铬钼合金钢管的成分使其成为在极高温度和压力下运输流体和气体的发电厂、炼油厂、石化厂和油田服务的理想选择。

Heat Treatment Requirements 热处理要求

|

Grade |

Heat Treatment Type |

Normalizing Temperature Range F [C] |

Subcritical Annealing or Tempering |

|

A335 P5 (b,c) |

Full or Isothermal Anneal |

|

|

|

|

Normalize and Temper |

***** |

1250 [675] |

|

|

Subcritical Anneal (P5c only) |

***** |

1325 – 1375 [715 - 745] |

|

A335 P9 |

Full or Isothermal Anneal |

|

|

|

|

Normalize and Temper |

***** |

1250 [675] |

|

A335 P11 |

Full or Isothermal Anneal |

|

|

|

|

Normalize and Temper |

***** |

1200 [650] |

|

A335 P22 |

Full or Isothermal Anneal |

|

|

|

|

Normalize and Temper |

***** |

1250 [675] |

|

A335 P91 |

Normalize and Temper |

1900-1975 [1040 - 1080] |

1350-1470 [730 - 800] |

|

|

Quench and Temper |

1900-1975 [1040 - 1080] |

1350-1470 [730 - 800] |

Material & Manufacture 材料与制造

Pipe may be either hot finished or cold drawn with the finishing heat treatment noted below.

管道可以进行热精加工或冷拔,并进行以下精加工热处理。

Heat Treatment热处理

- A / N+T

- N+T / Q+T

- N+T

Mechanical Tests Specified规定的机械试验

- Transverse or Longitudinal Tension Test and Flattening Test, Hardness Test, or Bend Test

- 横向或纵向拉伸试验和压扁试验、硬度试验或弯曲试验

- For material heat treated in a batch-type furnace, tests shall be made on 5% of the pipe from each treated lot. For small lots, at least one pipe shall be tested.

- 对于在分批式炉中热处理的材料,应对每个处理批次的5%的管道进行测试。对于小批量,应至少测试一根管道。

- For material heat treated by the continuous process, tests shall be made on a sufficient number of pipe to constitute 5% of the lot, but in no case less than 2 pipe.

- 对于连续工艺热处理的材料,应在足够数量的管道上进行测试,以构成该批的5%,但在任何情况下不得少于2根管道。

Notes for Hardness Test硬度试验注意事项

- P11 shall not have a hardness not exceeding 250 HB/265 HV [25HRC].

- P11的硬度不得超过250 HB/265 HV[25HRC]。

Notes for Bend Test弯曲试验注意事项

- For pipe whose diameter exceeds NPS 25 and whose diameter to wall thickness ratio is 7.0 or less shall be subjected to the bend test instead of the flattening test.

- 对于直径超过NPS 25且直径与壁厚比为7.0或更小的管道,应进行弯曲试验,而不是压扁试验。

- Other pipe whose diameter equals or exceeds NPS 10 may be given the bend test in place of the flattening test subject to the approval of the purchaser.

- 经买方批准,直径等于或超过NPS 10的其他管道可进行弯曲试验,以代替压扁试验。

- The bend test specimens shall be bent at room temperature through 180 without cracking on the outside of the bent portion.

- 弯曲试样应在室温下弯曲180度,弯曲部分外侧不得开裂。

FAQs About ASTM A335 Chrome Moly Pipe ASTM A335铬钼管常见问题

Q1. What industries commonly use ASTM A335 Chrome Moly Pipe?

Q1.哪些行业通常使用ASTM A335铬钼管?

It is extensively used in power generation, petrochemicals, oil and gas, and aerospace industries.

它广泛应用于发电、石化、石油和天然气以及航空航天工业。

Q2. Can ASTM A335 Chrome Moly Pipe withstand high pressures?

Q2.ASTM A335铬钼管能承受高压吗?

Yes, it is known for its ability to handle high-pressure environments effectively.

是的,它以有效处理高压环境的能力而闻名。

Q3. Is ASTM A335 Chrome Moly Pipe susceptible to corrosion?

Q3.ASTM A335铬钼管是否易受腐蚀?

While it can be prone to corrosion, proper coatings can make it highly resistant.

虽然它容易腐蚀,但适当的涂层可以使其具有很高的耐腐蚀性。

Q4. How is ASTM A335 Chrome Moly Pipe manufactured?

Q4.ASTM A335铬钼管是如何制造的?

It is produced through a seamless manufacturing process, ensuring its robustness.

它是通过无缝制造工艺生产的,确保了其坚固性。

Q5. What sets ASTM A335 Chrome Moly Pipe apart from seamed pipes?

Q5.ASTM A335铬钼管与有缝管有何不同?

The seamless construction eliminates potential weak points, making it more reliable under pressure.

无缝结构消除了潜在的弱点,使其在压力下更可靠。

扫二维码用手机看

- 联系电话- 0317-6689999 6165555

- 业务邮箱- 9905791@qq.com

- 公司地址- 河北省沧州市盐山县千童大街沧州银行对面

- 联系电话- 0317-6689999 6165555

- 业务邮箱- 9905791@qq.com

- 公司地址- 河北省沧州市盐山县千童大街沧州银行对面

版权所有:英国ladbrokes官方网站 冀ICP备19004948号-6

热线:0317-6165555

热线:0317-6165555 9905791@qq.com

9905791@qq.com